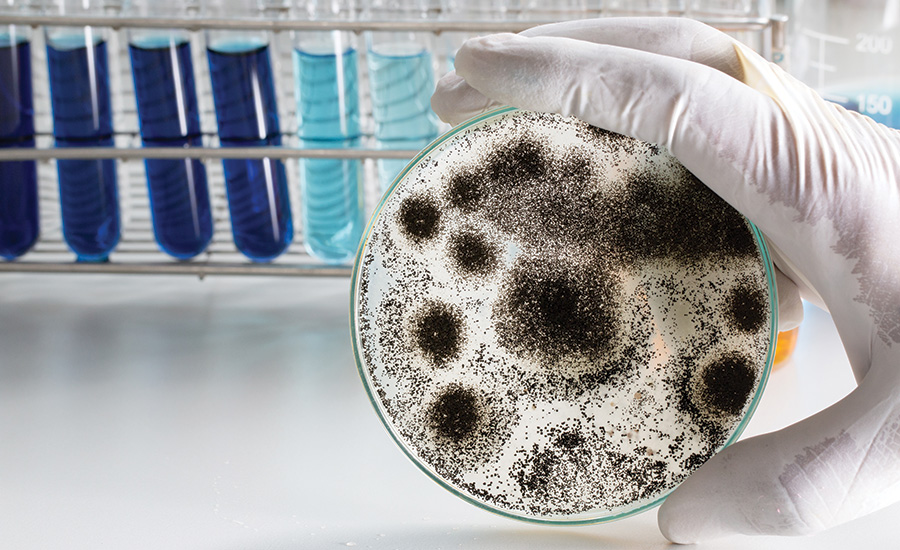

Restoration Chemistry Part 2: Mold Remediation Chemicals

For many people, discussions of chemistry are not only confusing; such conversations are actually scary. Too many individuals do not appreciate just how valuable a basic understanding of chemistry can be to their efforts as a cleaning or restoration professional. However, the value of a general knowledge of what chemicals are and how they work does not mean that someone has to wear a white lab coat and stand around bubbling glass beakers in a laboratory. To that end, the goal of this series of articles is to help the restoration and cleaning professional understand the basics about the various products used during their projects so they can:

- Take adequate safety precautions to prevent hazardous chemical exposures to their crew or building occupants,

- Have a base of information for making reasonable choices regarding chemical selection for different activities, and

- Understand enough about the products they are using so they can speak intelligently with customers, consultants, adjusters, occupants, and other project stakeholders.

Understanding Terminology

Restoration Chemistry Part I: Understanding the Benefits and Pitfalls of Using a Chemical on the Job Site

Revisit part I here!

Regardless of the industry or profession, every group has its own “twist” on common language to accommodate the specific terms which describe the activities that are unique to that group. For example, people who have even a little bit of experience in mold remediation have a baseline understanding of terms such as “colonies”, “fungal growth”, “normal fungal ecology”, “bioaerosol sampling cassette”, and “spores”. Their familiarity with mold remediation terminology may even extend to some of the terms that cross into the chemistry world, such as “antimicrobial” and “fungicide”.

Clinical Terms Typically Used in Mold Remediation

| Term | Definition | Notes |

| Antimicrobial | General term for drugs, chemicals, or other substances that kill or slow the growth of microbes | Includes antibiotics along with antibacterial, antiviral, antiparasitic, and antifungal products. |

| Fungicide | Chemical substance used to kill fungus or prevent it from growing | Also known as antifungal. Some fungicides are also fungistats |

| Fungistat | Chemical substance that prevents or inhibits the growth of fungi (sometimes without destroying the existing fungal colony or spore) | Fungistats can provide short-term protection from mold growth on surfaces or have long-term residual action which can limit growth for months or years |

| Deodorizer | A chemical used to conceal or remove an unpleasant smell | Many deodorizers that mask bad smells add to the overall level of chemicals in the air rather than reducing it |

| Cleaner | A chemical used to conceal or remove an unpleasant smell | Many deodorizers that mask bad smells add to the overall level of chemicals in the air rather than reducing it |

| Cleaner | Chemicals to get rid of dirt, dust, blemishes, and bad odors; usually from surfaces | Many cleaners are combinations of soap/detergent, water, and surfactants. Depending on the cleaner, it can be used on building surfaces or people |

| Sanitizer | A chemical used to decrease the amount of microbial contamination from surfaces | Specific industries have rules which specify what percentage of microorganisms need to be killed for product be labeled a sanitizer. The EPA requires a sanitizer to have a kill rate of 99.9% |

| Disinfectant | A chemical used to destroy, inactivate, or significantly reduce the concentration of pathogens (such as bacteria, viruses, and fungi | The EPA requires a disinfectant to have a kill rate of 99.999% |

| Sterilizer | A chemical that leaves the surface free of live bacteria or other microorganisms | The EPA requires a sterilizer to have a minimum kill rate of 99.9999% |

| Mold stain remover | A product used to lighten or remove discoloration caused by enzymes released by fungal organisms | Mold stain removers are typically more aggressive than stain removers designed for fabrics and carpets as they are often used on lumber and sheathing |

Or do they? Rather than make the assumption that individuals who are operating in the mold remediation field understand the real definition of terms that are bandied about with such frequency, it is better to start with a simple chart so everyone is building on the same foundation of knowledge. Some key chemical terms for mold remediation, and their proper definition, are provided here:

Digging Into The Definitions

Understanding the terminology related to chemicals used in mold remediation allows additional knowledge to be built onto that solid base. For example, looking at the notes for the term “antimicrobial” leads to the logical conclusion that every antifungal chemical is an antimicrobial. But a deeper look shows that the reverse is not true; some antimicrobials can be effective against bacteria or parasites but not work against mold; so, there are many antimicrobials which are not effective against mold.

There are similar logical deductions to be made when considering the terms of fungicide and fungistat. The fact that a fungicide kills mold means that it, by definition, keeps it from growing. What many in the mold remediation industry do not get is that certain fungistats do not kill the fungal organisms. If the mold comes in contact with the chemical, or a treated surface, it does not propagate. However, unless the fungistat also has some mold killing propertie the spore could move to a different location and start a colony. The best example of this is some of the HVAC filters advertise that they prevent mold growth. Spores may not be able to grow on the filters, but if they are on the filter for a while, get dislodged and move into the mechanical components, they could start fungal colonies in the drip pan or other wet areas.

Classes of Mold Remediation Chemicals

Another interesting fact that the definitions point out is that they are not mutually exclusive. In other words, the same chemical can be an antimicrobial, fungicide, and disinfectant depending on how it is formulated and registered. To make it more confusing, chemicals can be used for cross purposes. A sanitizer or disinfectant is often formulated so that it works well as a cleaner too. As such, many in the mold remediation industry end up using disinfectants during the cleaning process. That way the contractor provides some residual mold killing action if the physical process of cleaning is not completely successful in removing all of the colonies and spores.

The confusion that this interplay of terms creates means cleaning and restoration professionals should have a general understanding of the class of chemical they are using on different steps of their mold remediation project. Since the majority of chemicals used for mold remediation do carry the designation as a disinfectant, we can use that as a starting point. While it is true that a large number of chemicals have been utilized as disinfectants over the last 80 years, these nine are the ones that are in typical/frequent use today:

- Chlorine (bleach)

- Hydrogen peroxide

- Quaternary ammonium compounds

- Essential oils

- Alcohol

- Iodophors (iodine)

- Phenolics

- Formaldehyde

- Glutaraldehyde

Since the top four are the chemicals most frequently promoted for mold remediation, it is worth having a little deeper understanding of them. The first two classes of mold remediation chemicals on the list have an important point in common. Both chlorine and hydrogen peroxide are considered oxidizers because they either take in or give up loosely bound oxygen atoms from other compounds*.

Compounds that contain the element chlorine are chemically unstable so they are quickly inactivated by excess organic materials. What this means on a practical basis is that when bleach water comes in contact with the dirty surface, it quickly loses its ability to add and subtract oxygen atoms so its ability to break up microorganisms is lost. Although dirty or soapy bleach water may still smell like it is strong, that lingering odor is not reflective of its potency in dealing with bacteria or fungal organisms. Another significant concern for contractors using chlorine derivatives for mold remediation is its corrosiveness for many materials; including metals and living tissue. Still, it is quite common to see high percentages of chlorine being matched with hydrogen peroxide and surfactants in a number of the mold stain removers. While this combination allows the liquid to penetrate the surface and remove the discoloration, it also means that the products have a relatively short shelf life — months at best.

Since they are similar chemically, some of the same plusses and minuses that are attached to chlorine products go along with hydrogen peroxide products. Unless special additives are used as stabilizers, hydrogen peroxide can break down over time, even inside a closed container. Since light accelerates this process, hydrogen peroxide products are often packaged in opaque, rather than clear, containers. The primary benefits to hydrogen peroxide for mold work as compared to chlorine products are that the hydrogen peroxide does not have the same residual odor and it quickly breaks down into innocuous byproducts of water vapor and oxygen.

The Two Biggest Players

For mold remediation work of cleaning and killing fungus, the two most popular classes of chemicals are quaternary ammonium compounds and essential oils. Because of the length of the name, quaternary ammonium compounds are typically just referred to as “quats”. Quats are popular for mold work, and other situations where microbiological contaminants on surfaces are being addressed, because they have such a long history of effective use. Two other critical factors are that they are generally considered to be safe and that the chemistry is easily adapted so there are hundreds of individual formulations.

Still, there are downsides to quats. Like chlorine, quats easily bind to organic material, including soaps and extremely hard water. Therefore, surfaces that are going to be treated with a quat class of disinfectant should be clean and rinsed of soap residue before application. In addition, not all of the quat formulations are rated for viruses, fungi, and bacterial spores. From a health perspective, the overall safety of quats is tempered by the fact that prolonged contact with the skin can be irritating. Still, their wide range of effectiveness on the microorganisms, the fact that most of the formulations are noncorrosive, that quats are considered to be low in terms of toxicity, and that such chemicals are relatively inexpensive make them a favorite for mold remediation.

The class of mold remediation chemicals that has grown most rapidly over the last 10 years is formulated with essential oils. For the purposes of mold remediation, the best definition of essential oils is that they are chemicals extracted from plants that have naturally occurring antimicrobial properties. These chemicals are found in a wide variety of crops including herbs, citrus fruits, and tree leaves. The most common essential oils being marketed for mold remediation are connected with the herb thyme and citrus fruits such as orange and grapefruit. Although not as common in the US, tea tree oil is being promoted for mold remediation in many areas of the world.

The reason for the spectacular growth of essential oil products is their appeal as being “green” or “natural”. This does translate into products that can be safer for both the restoration contractor and the occupants. The fact that such chemicals have proven effectiveness as disinfectants and can also double as a deodorizer makes them very attractive for mold remediation work. But, be aware that concentrated chemicals, even naturally derived chemicals, can be irritating to skin and eyes.

Applying Chemical Knowledge To Mold Remediation

Once the cleaning and restoration professional has a basic understanding of the terminology that describes chemistry related to mold remediation, the product advertisements and instruction sheets make a lot more sense. They quickly realize that there is a lot of chemical “tools” in the toolbox. Nevertheless, whichever tool is chosen the restoration professional needs to follow the manufacturer’s directions and procedures for use. That means everyone on the crew, not just the lead worker or superintendent, needs to understand what chemicals are being used, as well as the safety precautions that are necessary. Therefore, it is especially important that any time a new chemical is utilized for mold remediation, a specific use protocol be put in place before putting the new chemical, and associated application equipment, into the field.

When it comes to chemicals for mold remediation, knowledge leads to safety!

*”Compounds” is the term used in chemistry for combinations of elements — the most basic substances found in nature that cannot be broken down by chemical reactions.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!