4 Steps to Contents Odor Removal Using Hydroxyls

Treating contents has always been, and always will be, a necessary component in the restoration industry. Unless a home or business is completely empty when damaged, there will be a variety of items that need attention. While many restoration companies sub out that work to professionals specializing in contents cleaning and restoration, it is becoming increasingly popular for contractors to take on that work themselves. This is a great opportunity for businesses to increase their profits, but with that responsibility comes an increase in necessary training and equipment.

There are many factors to consider when walking through a project that has contents. Can they be restored to pre-loss condition? What type of physical cleaning is needed? What type of repair work needs to be done? Are there sentimental or special items that can’t be replaced? Can this be done onsite or do they need to be packed out and moved offsite? Am I able to handle this task or should someone more qualified do it instead? These are all important questions to consider early on.

Let’s fast forward and say you decided to do the job. You meticulously recorded all of the items, packed them, moved them, washed them, cleaned them, repaired them, and stored them. The project is about finished so it is time to return all of the items to the owner. You load them all in the truck, drive them over, and proudly start unpacking everything. As more and more items are unwrapped and put back into place, you start to notice a problem. What is that smell?!? Yep, the items all look fantastic and have never been cleaner, but that pesky smell is back and now we have an issue. What happened?

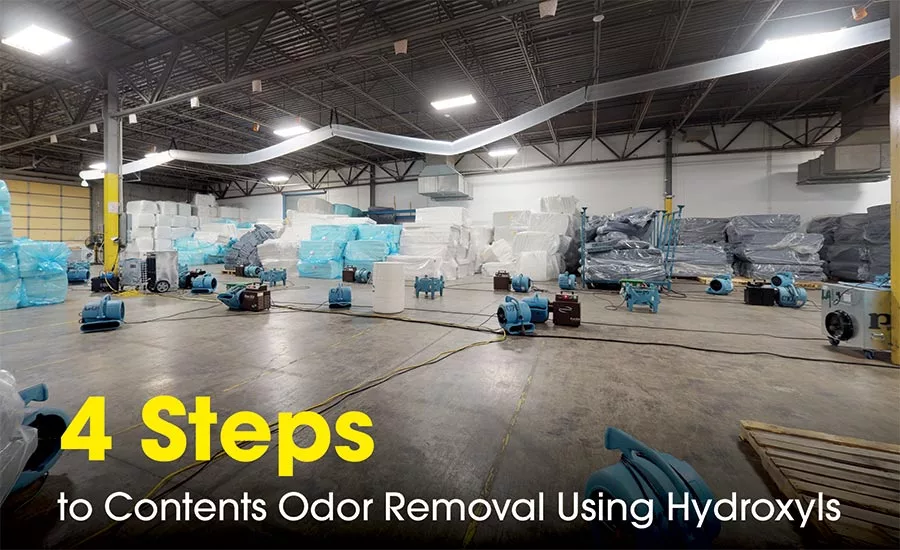

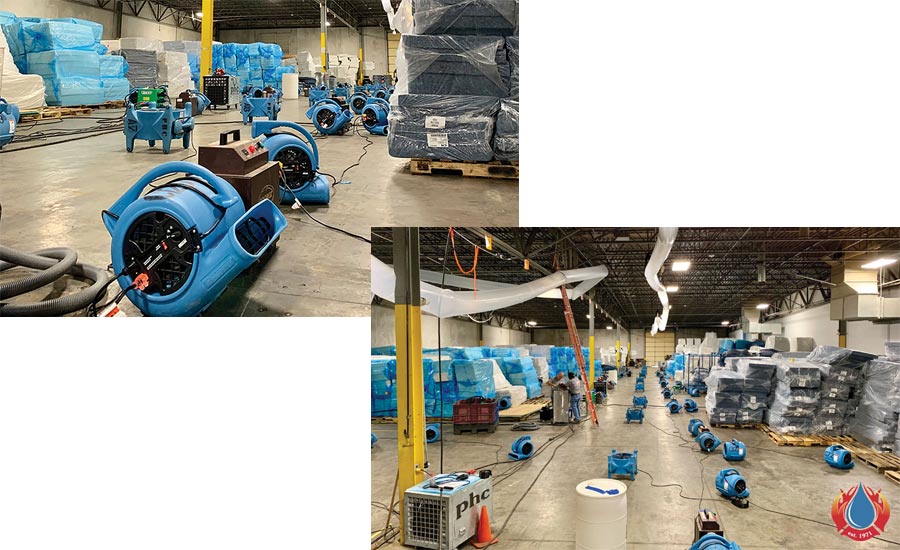

When items like this are affected by odor, there is no need to unwrap them. Instead, blast them with hydroxyls while keeping the items in place – like you see in these photos from a foam mattress warehouse that experienced a fire.

Odors in contents can be a tricky problem to solve because unlike physical damage, you can’t actually see the odor. To make it even more difficult, when you are dealing with extremely porous items that are thick, like couch cushions or pillows, how can you even GET to the odor? There are many options available to try to address this. The key with odor removal is to eliminate it, not mask or cover it up. Two of the most powerful oxidizing agents available to do this are ozone and hydroxyl radicals.

Ozone generators have been used in the restoration industry for decades, and most companies are familiar with how to use them. Typically, an ozone chamber will be created for the contents to be placed in, then ozone will be injected into the chamber. This is a very effective system for eliminating many different types of odors from items, and when used properly, can relieve a lot of the stress from the contractor in charge. However, in recent years, many companies have switched from the use of ozone to hydroxyls for various reasons – including safety concerns and possible damage to contents.

When pallets of cardboard boxes were affected by a fire, a creative restoration contractor packed them into a semi, put up containment, and treated the pallets with hydroxyls. This process effectively removed all odors and saved the inventory.

Since the use of hydroxyls is somewhat new to the industry, there is often some confusion about how to use them, when to use them, etc. While assessing a specific project, here is helpful, educational information to pass along to the property owner or client:

- Hydroxyls will never damage anything regardless of how long they run or how sensitive the items are.

- Hydroxyls are the second strongest oxidant in the world – which means they will eliminate almost every odor no matter what it is or where it is.

- There are no concerns about leaving behind a residue, chemical smells, or other irritating byproducts.

The following steps will help ensure this process gets handled as effectively as possible:

1) Understand HOW hydroxyls remove odor.

The air coming out of the hydroxyl generator is where you will find the hydroxyls. The goal is to get the air coming out of the machine into the items where the odor has been adsorbed. The closer you are to the machine, the higher the concentration of hydroxyls.

On that topic, it is important to realize there are two different types of hydroxyl generators. One uses a process called photocatalytic oxidation (PCO) where hydroxyls are only formed on the catalyst surface (titanium dioxide) inside the chamber of the machine. PCO systems work much like air scrubbers because they are only treating the air going through the machine and are not applicable for contents. The second type of hydroxyl generator does not use any catalyst; it was patented because of its ability to produce radicals outside the machine. The steps mentioned in this article apply only to that specific unit.

This is a prime example of how to target hydroxyl radicals into a specific, affected space.

2) Determine if contents should be treated on site, or packed out and treated off site.

Now that we understand the air coming out of the hydroxyl generator is where the hydroxyls are, we have to figure out the best way to get them to the contents. If contents are going to be treated onsite, it is best to leave them in the same places they were when the odors got to them. Don’t move them around too much or restack things. It helps to open doors, drawers, cabinets, etc. to give the air the easiest path to get to the hard to reach areas.

If items are being boxed up and taken off site, they should be taken out of the box and placed in a hydroxyl chamber or some type of contained area. Try to remember how the contents were before they were boxed and do the best you can to recreate a similar scenario. For example, if clothes were hanging in a closet, try to hang them in the treatment area as well.

3) Focus hydroxyls on affected contents.

When setting up a hydroxyl chamber, hydroxyl generators can either be placed in the room or the hydroxyl radicals can be injected into the room. Most companies prefer placing generators right in the room. Hydroxyls, as a gas, will naturally fill up the room and penetrate all the items to disassemble, and thus eliminate the odor molecules. To be clear, this results in permanent elimination of the odors and can give both the contractor and the owner of the contents the peace of mind knowing the odor will never come back.

When setting up the machines, it is as simple as plugging them in and turning them on. There is a common misconception now that you need to add humidity for them to work. This is not accurate. Many contractors use hydroxyls while drying structures or placed in drying chambers for rugs and other items, and you certainly do not want to add humidity to that. Whether you’re at 5% or 95%, the machine is going to work the same.

If contents are being treated onsite, there are a few variables to consider. First, the recommended coverage area is 1,000 – 1,500 square feet. Keep in mind if you are in a smaller area, you will get a higher concentration of hydroxyls and they will work more quickly. If you are treating a larger area, you will get a lower concentration, and the job will take a little longer. Second, pay attention to dividers – walls, closets, bathrooms, hallways, multiple floors, etc. Remember, you’re getting the air coming out of the machines to hit the contents, so the layout is a factor. Finally, be strategic with your placement of machines. If you need a really high concentration in a specific area, contain that area to get it done more quickly.

From this angle, you can see how a containment barrier was used to trap and push hydroxyls right into hidden and hard-to-reach areas.

4) Run machines until you can 100% verify the odors are gone.

So how do you know when the odors are 100% gone? While this answer will seem a bit simple, it is very important. When you think the project is done, you need to turn off all of the machines. Use your nose, put it directly on the materials you’re testing, and smell. That’s it. If the smell is not noticeable at all, you’re good. If you still pick up a hint of odor, the job isn’t done. Your options are run the machines longer as is, add more machines, or move them around to focus on the areas where there is still an odor. Do not turn off the machines and walk away if you can detect any odor.

For those of you already experienced in the contents restoration field, new to it, or are thinking about getting into it, hopefully this information helps address one specific area. There is a lot of profit to be made in this field, and a lot of customers to benefit from restored items, and hydroxyl generators are a key component to the process.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!