Sponsored by: Graco

Challenging the Odds: When a Customer Gets Spooked | Case Study Contest WINNER!

Photos courtesy of Kowalski Construction.

Photos courtesy of Kowalski Construction

Photos courtesy of Kowalski Construction.

Photos courtesy of Kowalski Construction.

A tale of 1,000 Syringes, All Cleaned Up LLC, Nevada.

A tale of 1,000 Syringes, All Cleaned Up LLC, Nevada.

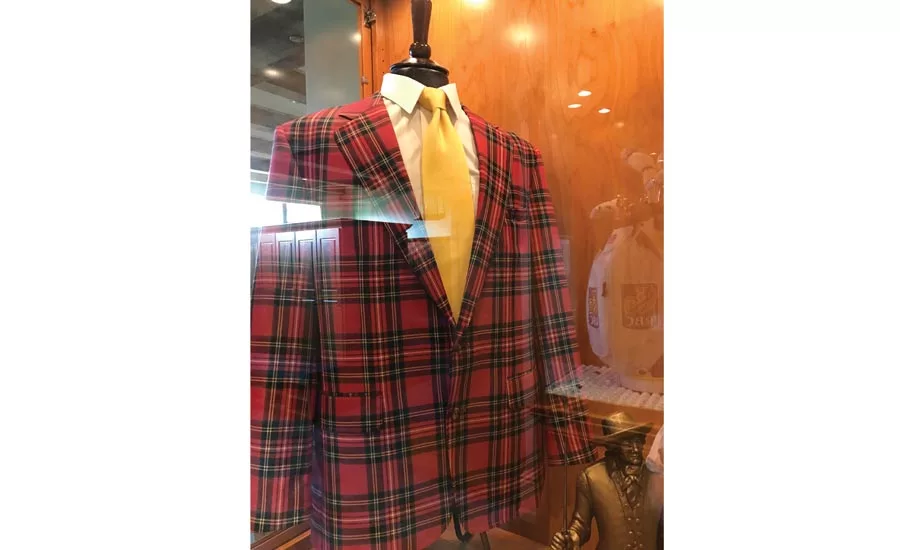

Restoring where the greats tee off, Rainbow Int'l of Monroe, Michigan.

Restoring where the greats tee off, Rainbow Int'l of Monroe, Michigan.

Editor’s Note:

This year’s 4th Annual Case Study Contest, sponsored by Graco, was a great success!

Thank you to the nine companies that submitted case studies, and to everyone who voted!

In all, 2,104 votes were cast in a short three week window, and the winning entry gobbled up 54 percent of the votes, thanks to the amazing power of social media sharing and rallying!

“Everyone was nervous about everybody else. We knew something was up right from the start; it really put a strain on everything, and understandably so.” --Jim Kowalski, Co-Owner, Kowalski Construction

It was monsoon season in Phoenix, Ariz. in 2016, when the phone rang at Kowalski Construction about a section of roof that had blown off a large warehouse. It didn’t take long for the Kowalski Construction team to realize this wasn’t going to be just another large loss. During the initial on-site conversation, the team learned the client had very recently had a nearly identical loss in the $3 million range, and that claim was now part of a court battle.

“Tensions were high on both the insurance company and ownership sides as everyone was aware of the ongoing litigation,” Jim Kowalski, co-owner of Kowalski Construction, explained about the loss. “Managing everyone’s expectations and preventing this claim from also becoming a legal nightmare turned out to be the biggest challenge of all.”

With everyone concerned this would explode into another massive claim, the Kowalski Construction team forged ahead, with the plan to communicate, communicate, and communicate some more.

“We told them everything. It’s like that old saying – tell them what you’re going to do, tell them what you’re doing, and tell them what you’ve done,” Jim said. “Keep it all above board, and when there is a glitch, get it out there early and take care of it so it doesn’t look like you’re hiding anything.”

The Logistics

Aside from the obvious challenge with a jumpy client and insurance carrier, this was truly a massive job requiring some outside-the-box thinking. The warehouse itself was 111,159 square feet; a 3,900-foot section of roof had been blown off. Jim described the size of the warehouse as several times the size of a Super Walmart. In addition, there was a mold infestation that had to be remediated, and a roof truss that was broken. From the beginning, it was all hands on deck with 50 to 60 people working at the start of the project.

Before any remediation work could get going, the Kowalski Construction team had to figure out what to do with merchandise (we’ll explain more about the merchandise a little later) from the warehouse that was fully stocked. The racks were spaced so closely together, the 40-foot scissor lifts initially wouldn’t fit into the space where demo and repair work needed to be done. So, crews worked tirelessly and quickly to remove four sections of racking, which entailed organizing and removing more than 2,500 pallets of merchandise from the warehouse. That project alone required three semi-trucks running around the clock for two days.

“With the merchandise and racking out of the way, we built a 40-foot by 65-foot wooden platform on top of the existing racks in order to provide a base from which we could access the ceiling,” Jim explained. “We built railings and outriggers around the perimeter to better secure an area; a huge containment was also erected in order to protect the unaffected areas of the warehouse.”

From there, 11 negative air scrubbers were used during the mold remediation process which, upon closer inspection, was found to cover a larger area than originally thought.

When the larger area of mold was found, the platform had to be expanded by 20 feet, and the containment area stretched further. Plus, the overhead lighting had to be replaced, so a temporary, battery-powered lighting system was assembled as well as an additional power panel to run all the necessary remediation equipment.

Details to Note

While those were all the basic logistics of the job, there were a few other things that made this project unique. Perhaps the most interesting piece is that an international adjuster was involved on this job. When the adjuster first met with Kowalski Construction, he explained how he traditionally only handles multi-million dollar losses, and travels around the world doing so. There are only a handful of adjusters like this in the world. Due to the in-progress lawsuit, he was sent to be involved on this loss, which Kowalski Construction was able to complete for just over $200,000. Kowalski Construction actually found some benefits in working with an adjuster like this.

“Our experience has been the more experience the adjuster has, the better they are to work with,” Jim said. “It’s a better fit for ours and probably most companies. They are more savvy and knowledgeable, and that’s an easier combination to work with than someone who doesn’t have the experience. It worked out really well.”

It should also be noted that the contents in this warehouse were of great concern to the client. The warehouse was packed to the brim with Halloween costumes, makeup, accessories, and so on. Due to the nature of the contents, it was critical that mold spores were contained, and as little of the product was affected as possible. The 2,500 pallets of goods we mentioned earlier that had to be removed from the building were destroyed by the monsoon damage. The rest of the stored items survived.

Success in a Scary Situation

Kowalski Construction was able to effectively and efficiently get this tricky job completed within two months, and fully gained the trust of the client, carrier, and international adjuster.

In July 2017, another monsoon swept through the Phoenix area, doing even more damage than the last storm. The company called Kowalski Construction directly to handle the remediation. This time around, the team knew what they were up against logistically, and the history of the property, and were ready to tackle the damage head-on with the full confidence of the client.

Runner Up #1

A Tale of 1,000 Syringes

All Cleaned Up LLC

Nevada

All Cleaned Up was called to clean an apartment that a young man was living in and had destroyed. When the team arrived, there was a lot of evidence of heavy intravenous drug use, heroin free basing, large amounts of cat urine and feces, along with squalid living conditions. There were built up trash piles in all areas of the apartment, cat feces throughout the entire apartment including in the bed in which this man was sleeping, 1000+ syringes, 1500+ square aluminum foil pieces, urine-soaked clothing, bedding and carpet in both bedrooms and through the bathrooms, and bottles full of urine and vomit in his closet. There were areas in which the drywall was so damaged by cat urine it needed to be removed and replaced. Most of the interior doors were also damaged and needed to be replaced.

The team started by building a cleaning plan that began with the needle removal first, trash removal second, followed by removal and inventory of the salvageable personal items. Carpets, doors, and most base boards were removed followed by the blinds. An enzyme cleaner was used to remove the human and animal waste and every surface cleaned from the ceiling down. Everything was then disinfected with a ULV fogger. Testing confirmed the apartment was then safe for new tenants.

Runner Up #2

Restoring Where the Greats Tee Off

Rainbow Int’l of Monroe

Monroe, Mich.

As Hurricane Matthew was barreling into the east coast in October 2016, all restoration contractors were watching the weather channel and tracking the storm on radar. Jason Kitts of Rainbow International of Monroe, Mich., traveled to Hilton Head to help, but while observing other members of the large loss team, he struck up a conversation with a construction manager, Tim, at Sea Pines Golf Course who said there was a little water in the basement.

Due to the destruction on the island Kitts suspected there was more damage than the eye could see. Kitts has been in situations like this before and was prepared with an infrared camera. He used the infrared camera to investigate many areas of the building including the walls and was able to see quite a bit of moisture that couldn’t be seen with the naked eye. He knew he had an equipment vendor on hold waiting and access to specialty labor companies and supply and material distributors as well as specialty equipment vendors.

They worked on seven different properties in six different locations: golf course building, The Inn at Harbor Town, two restaurants, two store front shops. By the time they left, they had completed all the mitigation and temporary repairs to both the golf resort and Inn. Three weeks after Rainbow being onsite the inn and golf course were 95% back operational.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!