Innovations in Restoration: Thermal Imaging Technology

Using thermal imaging technology in restoration

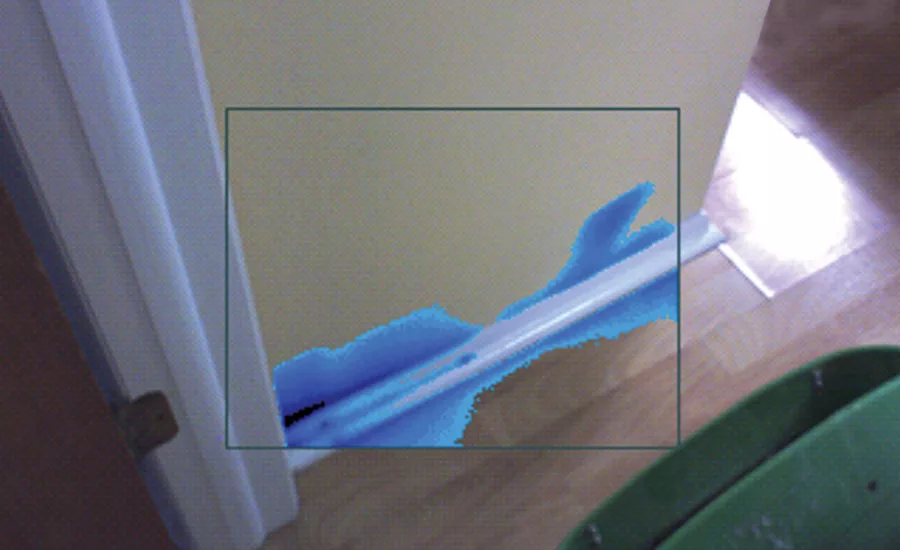

Often, moisture problems are not in the most visibly noticeable locations, as infrared discovered here in this wood- paneled wall and dark, low-pile, loop carpeting.

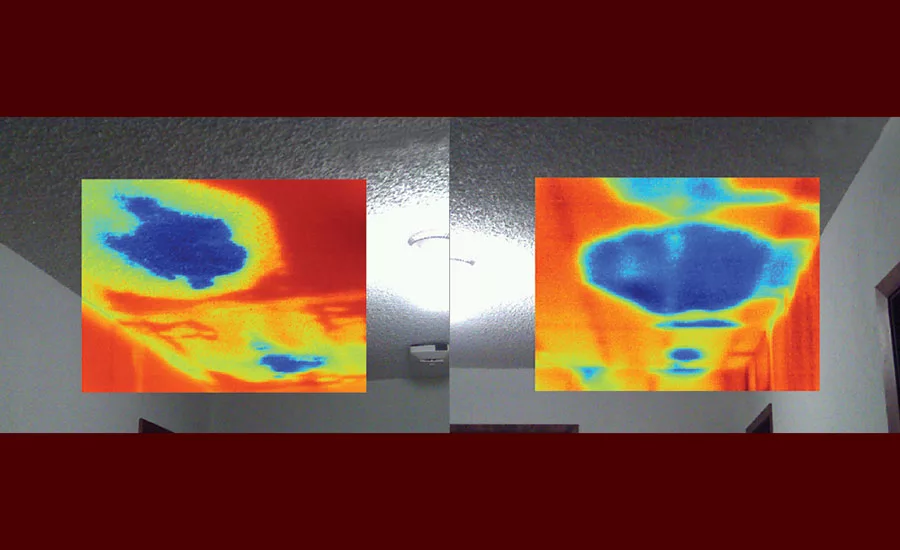

Many thermal anomalies can appear very similar, almost indistinguishable, in infrared.

At first, the darker blue region was thought to be a normal pattern seen in many wood-frame buildings, that is quite common on corners. The larger light-green area below was a clue that something more was happening, however. In fact, this was a result of a water leak in an adjoining upstairs room.

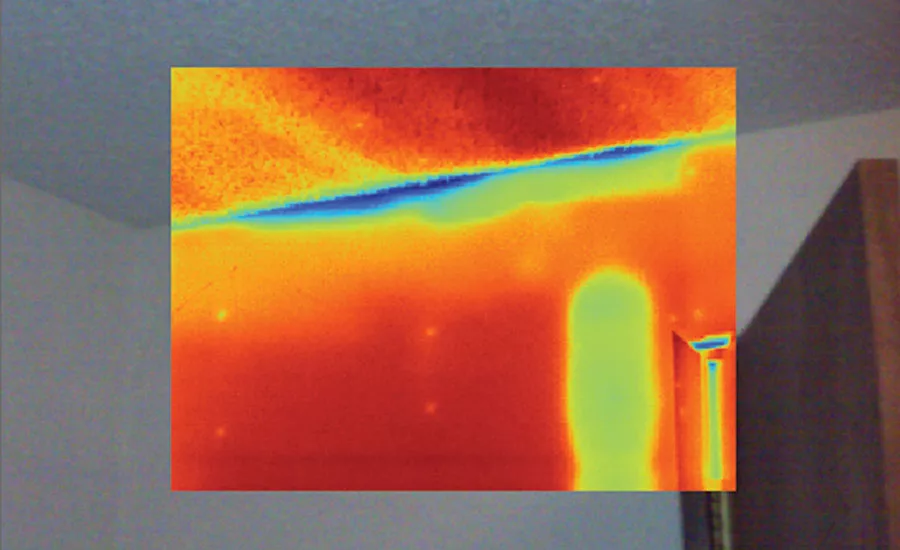

Visibly, the floor and wall look fine, but this IR-Fusion® technology infrared image shows that there is an issue. In this case, it was confirmed to be unexpected moisture.

These two infrared images show where water from an unattended bathtub overflow in an upstairs room had entered the interstitial space between the floors and pooled on the drywall of the downstairs ceiling. Knowing the location and extent of moisture infiltration is critical in determining the best course of remediation.

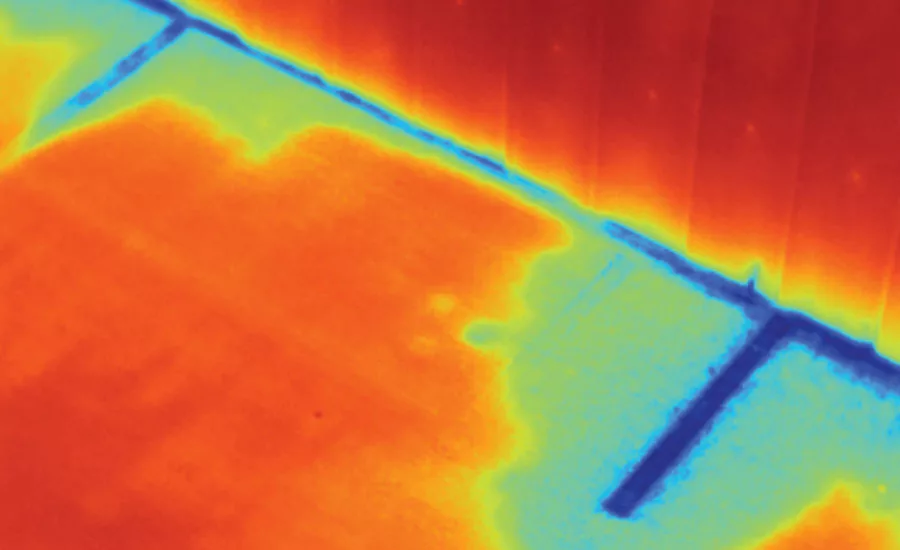

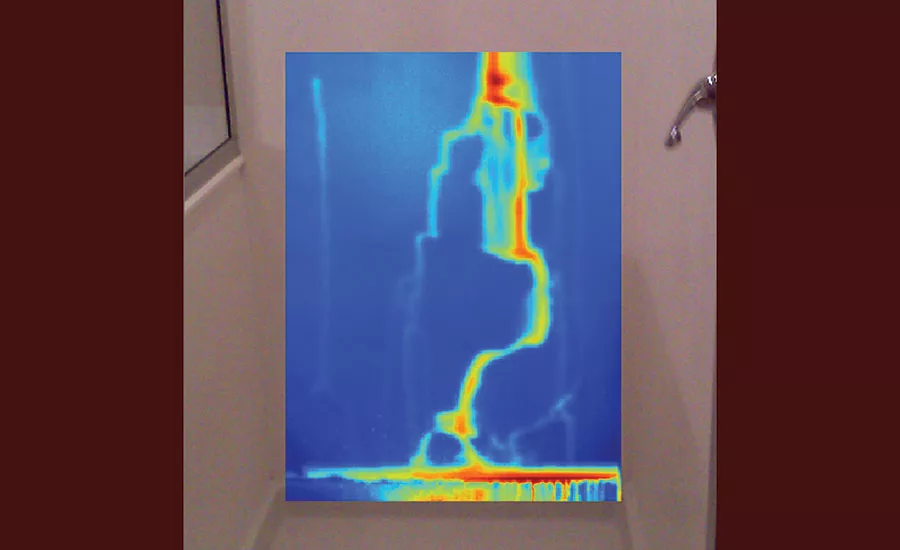

This infrared images clearly shows the heat from hot water leaking out of a supply pipe down the inside of the plumbing wall cavity behind the shower panel. Pinpointing the approximate location of this leak saved considerable time, effort, and money in resolving the issue.

The use of thermal imaging has become pretty common in the restoration industry. Detecting a temperature difference behind a wall can save big bucks and time by avoiding the need for demolition, and give remediators an early idea where the source of a water problem may lie. In essence, a thermal imaging camera is like a second set of Superman-style eyes. However, while Superman could physically see through a wall, IR cameras simply show you the surface temperature difference - but often give the illusion you are seeing through a surface. It takes knowledge about thermography to truly know what all those colors on the screen mean.

Michael Stuart has been working with thermal imaging technology for the last decade. Today, he is a thermographer for Fluke, a company specializing in thermal imaging cameras. Stuart feels as a product expert, he’s better able to connect with potential customers. Until the last decade or so, thermal imaging technology was out of the reach of the general contractor. But now it’s a rather widely-adopted skill.

“I like to do it, see it, and feel it for myself,” Stuart said. Thermographers who truly understand the science are able to determine things a newbie tech with a thermal imaging camera in hand would not.

John Anderson is a thermographer with FLIR, another company specializing in this technology. He has nearly 25 years of experience in the building and construction industries, and like Stuart -- a wealth of knowledge on thermal imaging and infrared technology. Anderson compares trying to find moisture in a room without an infrared or thermal camera like walking around with a blindfold.

“You might get lucky and find the wet spots, or you may not,” he said. “Thermal cameras serve to guide the user to the cold spots usually associated with moisture.”

For restorers, there are several key areas where thermal imaging can help. Most commonly, thermal imaging is used to find the source of a roof leak, condensation issues when something within a building fails, leaking pipes, and other similar water issues or air flow issues. It could also be used at a fire damage job – tracing the mess left by the sprinklers or fire hoses.

“Any number of things can get moisture into those building materials, and that just creates another set of nightmares if it’s not taken care of properly,” explained Stuart.

He lives in the Seattle, Washington area, where moisture problems are abundant.

“A large portion of the old homes in the Seattle area don’t always perform that well,” said Stuart. “There are a lot of moisture problems because we just didn’t know how we were building things. The reasons for moisture can be very, very different, but the end consequence is moisture in the space, which can deteriorate the structure, and trigger mold growth.”

Thankfully, skilled restorers with a thermal imaging camera can detect problems early, before the black, moldy spots appear. However, that temperature difference does not always indicate moisture or water.

“It could be cool air from outside,” Stuart warned. “It requires some skill to determine if it’s one thing or another.”

“For example, some thermal imaging devices allow restorers to add a pin probe or surface moisture meter. That will give a clearer indication if a temperature change behind the wall is a gap in insulation, or a moisture problem. It can essentially back up what your IR camera is seeing.

“The main thing restoration contractors need to know about the science of infrared cameras is these cameras measure the heat radiating from an object, plus heat reflecting off that object from the area around it.” Anderson explained.

Anderson explains until the colder areas associated with moisture evaporation are then verified with a traditional moisture meter, one should never blindly assume that cold equals moisture.

Stuart says the cameras are “just a dumb tool, another passive set of eyes that see something in a different wavelength than our own.” After a while, however, a restorer’s trained eyes will notice patterns based on materials, construction techniques, and other factors that show up on a thermal imaging screen.

Plus, once you identify the problem and begin the remediation process, an infrared camera and imaging moisture meter can help monitor the process.

“The user can quickly see what areas need additional attention, redirect fans or dehumidifiers, and measure the process as it happens,” said Anderson.

Make sure YOU are the trained set of eyes

Proper education is key. Stuart says it’s up to trained professionals to train the end user so they don’t see a restorer with a thermal imaging camera in hand and think it’s magic. Anderson agrees, reinforcing that a lack of proper training can result in false or incorrect inspection reports.

He recommends at least one person in every organization utilizing thermal imaging cameras have a level one qualification (or higher) from the American Society for Nondestructive Testing (ASNT). The organization offers three levels of qualification by way of about 30 hours of class time, hands-on training, field time, and even application-specific training.

“For people who are really serious about it, try to get your level one qualification if you can,” Stuart said. “If not, at a bare minimum, have someone in your organization with a level one who can then be serving as the go-to person, and all the other folks in the organization.”

Stuart recommends everyone else in the organization at least have a thermal imaging for building applications course under their belts.

Basically, restorers need to understand how their camera operates and its limitations, basic theory and mechanics behind the infrared energy and what that temperature difference means, and knowledge of building structure to make proper diagnoses.

“You can get pretty good at it in a pretty short amount of time,” Stuart said. But in the same breath, he said going out and buying a cheap product without training will result in a disservice to your company and your customers.

Be aware of cheap alternatives

You’ve likely seen apps boasting thermal imaging technology, but Stuart compares that option to playing a Beethoven symphony on your cell phone, versus though a Bose surround-sound audio system.

Anderson warns of the same thing. He says the so-called thermal and infrared camera apps for your smart phone can’t actually see heat. Instead, these apps are design filters that change the colors produced by the camera.

However, some companies that make thermal imaging cameras do offer a separate camera attachment that would run through their own downloadable app. Just be aware that while this might be a good option for the initial step of adding thermal imaging to your tool kit, the quality won’t be as good as a standalone device.

“You don’t want a mechanic using tools from the five and dime, or tools bought out of a truck,” Stuart said. “You get what you pay for. With a lot of the consumer’s electronics-type stuff that’s popping up in the marketplace, the performance just isn’t there for restorers to properly diagnose what’s going on. As resolution and power decrease with the price, you lose the ability to see nuances.”

Once you have all the right knowledge to back up what you see through your thermal imaging camera, the sky is really the limit.

When the job is done, pull that camera back out and show the client or adjuster the new temperature reading – dry, fixed, good as new.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!