Creating a Culture of Safety

4 ways to weave safety into your restoration company’s DNA.

Editor’s Note:

Lisa Lavender, the COO of Berks Fire Water Restoration, writes a monthly Restoring Success column featured the first Friday of every month in R&R’s eNewsletter, and on www.randrmagonline.com. This is one of Lisa’s latest columns – and the website version includes links to other resources, training videos, and more! Be sure to subscribe to our eNewsletter, and check our website often for new, educational content just like this that you won’t always find in the print issue!

As an organization, we have both moral and legal duties that relate to PPE. As presented in a previous Restoring Success column, the foundation of any safety initiative in your company is culture and attitude towards safety. PPE is important to protect the biggest and most important part of the company, the people. Beyond the team, we also have to consider the PPE needs and considerations for others that include but are not limited to: customers, adjusters, subcontractors, and inspectors.

By definition, personal means: of, relating to, or coming as from a particular person; individual; private. PPE (Personal Protective Equipment) relates specifically to the protection of an individual. As a company, PPE must be proactively managed; as an individual you must also take personal responsibility for your own PPE.

In the world of restoration, there are a number of variables that go into determining PPE: conditions, products, tools, equipment, and vehicles (Seatbelt = PPE – BUCKLE UP). Managing PPE within our companies is a combination of:

- Education & Training

- Accessibility & Inventory

- Proactive Management

- Culture of Safety

The following is a list of a various ideas, resources, and requirements to help your company manage PPE for success.

Education & Training

PPE training is accessible and readily available from a variety of sources.

Consider having someone in your organization dedicated to training others on the proper use of PPE in your organization. This allows for training and retraining on a regular basis and also allows for PPE to be easily integrated into your on-boarding protocol for new team members. Videos are also a great way to provide a quick engaging training session!

Most technical training courses, including IICRC courses include thorough training and even testing of PPE requirements. The IICRC also offers a Health and Safety Technician (HST) Course and certification that provides industry specific training and credentialing.

Bloodborn Pathogens

Bloodborne Pathogens training is to be provide, per OSHA 1910.1030, “at the time of initial assignment” and “at least annually thereafter.” This standard also details the employer’s accessibility to PPE requirement.

Respiratory Protection

Respiratory Protection: OSHA requires a variety of items that involve respiratory protection. It is critical that our organizations implement and manage our respiratory programs within the OSHA guidelines which includes but is not limited to annual fit testing. Establish a system and have accountabilities in place for this to be proactively managed and have appropriate records.

Many types of respiratory protection require a clean shaven face. I recommend that during the interview process, the company explains to candidates with facial hair that they will need to be willing to shave for annual fit testing and whenever a condition requires the use of the respirator. Razors must be kept in PPE bag at all times.

Labels and SDS (Safety Data Sheets)

Individuals should make a habit of reading labels and SDS sheets on products and utilizing PPE as appropriate. As an organization, we must comply with OSHA’s Hazard Communication Standard (HCS) “Employers must ensure that SDSs are readily accessible to employees.” Every couple of months remind your team to read their labels and wear the appropriate PPE, catch your team members protecting themselves properly and acknowledge a job well done.

Accessibility & Inventory

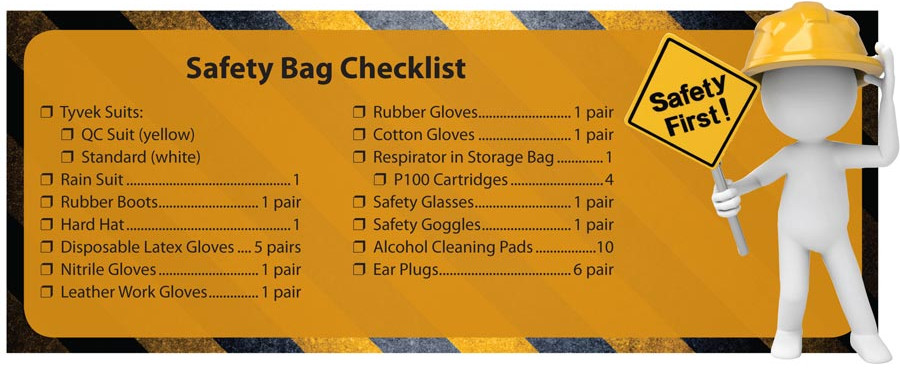

Consider issuing each new team member a PPE bag, fully stocked, with an inventory tag. Everyone is responsible for keeping their personal bag stocked in accordance with the tag and keeping their bag with them at all times. To reinforce the importance of always having your PPE with you, spot check both presence and stock of bags during job site inspections. An example tag may look something like:

Organizations must also have a process to manage the inventory and continually restock. Keep it front and center to your teams traffic flow and easily accessible which will promote bags being stocked and keep safety top of mind.

Tools and equipment that require the use of PPE should be stored with the appropriate specialty PPE. For example, when operating a chain saw, leg protection is required, store chaps, leg protection, close or with the chainsaws.

All outfitting for efficient deployment should include the appropriate PPE for the task. For example, a biohazard kit should have all the tools, supplies and PPE needed for a team to render a biohazard.

Proactive Management

Personal Protection Equipment, PPE, is an important element to an organizations safety program. The list is to present tools to begin PPE for success. There are many elements that were not addressed from PPE of others to vaccinations. You must also manage the inventory, maintenance, and storage of PPE. OSHA provides great tools and guidance to help you evaluate your PPE management on osha.gov.

Many of your suppliers, workman’s compensation insurance provider, insurance agents and other industry partners have support, guidance, and training available. Also, make sure that all the details and processes are being managed properly by your systems and team.

Culture of Safety

Weaving each of the first three elements together will help you create a culture of safety throughout your entire company; it becomes part of your company’s DNA. Before you know it, safety will be simply second nature, and your teams will be more accountable for their actions – and the safety of their teammates as well.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!