Infection Control: Work Beyond Cleaning & Insurance Claims

Adding a hospital-healthcare disinfectant to your toolbox to address infection control in healthcare facilities creates the opportunity for you to be on call for not just emergencies, but for routine and critical cleaning jobs, creating a revenue stream not dependent upon insurance claims.

When considering products and technologies, the choice of a disinfectant is a difficult one. The product needs to fit the healthcare environment and assure complete disinfection. It must be compatible with other agents in use and should be safe and odor free. It should be compatible with surfaces such as equipment, sensitive medical tools and devices, and electronics with no damage. It also must have a rapid turn-around time.

Dr. Helene Paxton, MS, MT(ASCP), PhD, CIC, Infection Preventionist St. Francis Healthcare System / Adjunct Professor Rowan University SHEA, APIC, ASM discusses the differences and unique considerations in common disinfection technologies in the healthcare space.

Q: How does AIHP technology differ from standard vaporized technology?

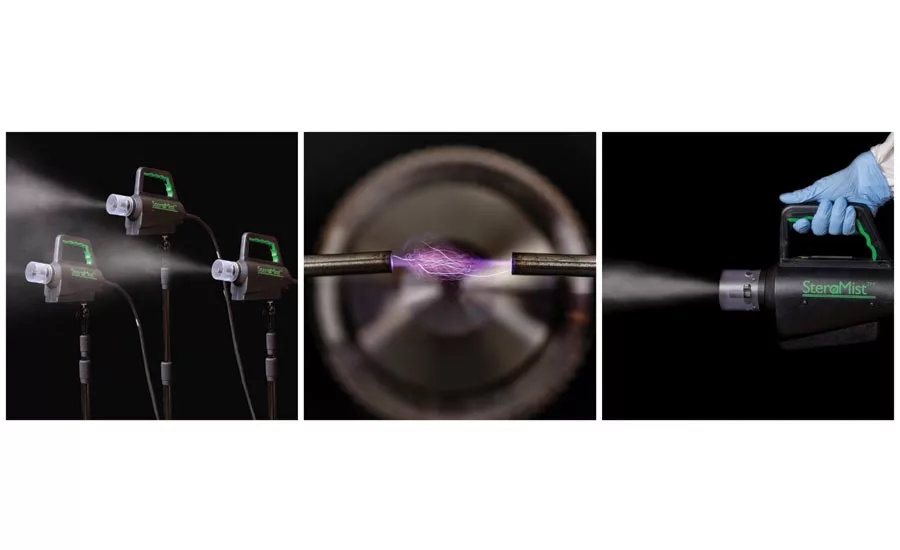

A: Dr. Paxton: Vaporized applications only nebulize highly caustic percentages of hydrogen peroxide. AIHP application is a real science that alters the molecule of hydrogen peroxide in which it allows its derivative, a reactive oxygen species, mostly hydroxyl radicals, to react with pathogens resulting in a 99.9999% kill of spores including C. diff spores.

Q: How is AIHP technology contributing to and enhancing manual cleaning practices?

A: AIHP (Activated Ionized Hydrogen Peroxide) technology goes above, beyond, under, and around disinfecting sprays and wipes to achieve a more thorough disinfection in hard to reach areas. AIHP is quicker, with no wipe no rinse, and the efficacy is NOT based on an antiquated nebulized vaporized technology.

Q: The UV/vaporized device marketplace is a crowded one; how is AIHP different?

A: UV is an unregistered science/technology thus results in a crowded marketplace. UV is also hard to achieve consistent data from and is cumbersome to use. We all know that it is only a matter of time until the regulatory officials mandate UV to undergo the same efficacy studies that hydrogen peroxide-based fogging technologies undergo. With UV being line-of-sight radiation and such short distance kill results, efficacy in a total room may be hard to pass.

The AIHP platform starts with a low concentration (7.8%) H2O2 solution and is converted to Reactive Oxygen Species, specifically the hydroxyl radical, by passing though High Energy Atmospheric Cold Plasma activation. This breaks the double bonds of the H2O2 creating the highly effective OH radical. This process is the first EPA-registered solution + equipment combination that provides the unique technology of hydrogen peroxide ionization for hospital-healthcare disinfecting.

Q: How does AIHP address factors such as cost, turnaround time, shadowed areas, and other factors that healthcare decision-makers identify as barriers to adoption?

A: AIHP is economical, non-corrosive, easy to apply, requires no wipe, no rinse, and leaves no residues. Due to the gas-like properties, it is not affected by shadows and can reach all crevices and hard-to-reach areas often missed by manual spray and wipe and UV light technologies. It does not contain any other additives that leave a residual or offensive smell like paracetic acid. AIHP does not use silver (Ag+) ions leaving environmental concerns. A quick turn-around time of 12-20 minutes can be achieved depending on size of room compared to 1-2 hours for most other fogging systems.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!