Safety Data Sheets: The User Manuals for Chemicals

Photo credit: bluekite/E+ via Getty Images.

What are the most basic items a restoration company needs to perform its work? Initially, what comes to my mind are moisture meters, air movers and dehumidifiers. Add trucks or vans to the list to move technicians and equipment to the jobs. Now, one of the keys to understanding how to properly use this equipment is the user manual. More specifically, the manuals tell us how to use them correctly and safely.

I would also say that chemicals are very important items for a restoration company. Chemicals perform work that we can’t physically perform. So, if our equipment comes with user manuals, where are the user manuals for our chemicals? What tells us how to use them correctly and safely? That’s easy – the Safety Data Sheet! The Safety Data Sheet, or SDS, is quite simply the user manual for our chemicals.

In this column, I’d like to show you some of the most valuable parts of an SDS, how the U.S. Occupational Safety and Health Administration (OSHA) expects us to manage SDSs, and then give you some reference information. In other words, let me introduce you to the chemical user manuals.

SDS or MSDS?

Prior to 2012, OSHA had the Hazard Communication Standard (1910.1200) that required employers to maintain Material Safety Data Sheets, or MSDSs. Then, in March 2012, OSHA modified the standard a few ways, which included adding the Globally Harmonized System (GHS).1 With the GHS there was a shift to Safety Data Sheets (SDSs) that standardized their content and formatting into 16 sections. The content and formatting are mandatory for chemical manufacturers to include in their SDSs.

I remember these changes coming out and I was initially dreading having to train employees on changes to a longstanding document. Change is never easy, for the user and the trainer! Then I dug into the new SDSs and my dread was replaced with relief – the SDSs were much better! In my opinion, this made understanding and using chemicals easier. Why? Let me point out three key parts of the SDS that makes it more informative and easier to use.

First key part: 16 SDS Sections

The 16 mandatory sections2 in an SDS make it easier to find important information because all SDSs are the same. For instance, if you want to know the recommended personal protective equipment (PPE) for any chemical or substance, you can go to Section 8, Exposure Controls/Personal Protection. Previous MSDSs were inconsistent with the location and content of PPE information.

Second key part: Section 2 - Hazards Identification

Section 2 of an SDS is more informative because of how the content must be presented. For instance, there are GHS pictograms. According to OSHA, the pictograms “…alert users of the chemical hazards to which they may be exposed.”3 I completely agree. A picture is worth a thousand words, right? Look at a few of them below.

Figure 1: Flame/Flammable Materials Hazard3

Figure 2: Health Hazard3

Here’s another example of simplicity: The “Signal Word.” There are two choices for Signal Words, “Danger” and “Warning.” Figure 3 below shows an example of a Signal Word and pictogram from Section 2 of an SDS. Danger is used for the more severe hazards. Warning is used for the less severe hazards. So, with just two words we have another informative, easy way to understand the hazards.

These elements of Section 2 allow a very quick understanding of the hazards. Even better, when you have a choice of using similar chemicals for a job or you have a new chemical you are trying for the first time, you can quickly compare the hazards of those chemicals by looking at Section 2.

For more information on this, OSHA goes into detail on labels and pictograms in their OSHA Brief, “Hazard Communication Standard: Labels and Pictograms (DSG BR-3636 2/2013).”

Third key part: Section 3 – Composition/Information on Ingredients

Section 3 of an SDS is also more informative because it consistently lists the chemical ingredients. Why are ingredients important? Because the more time you spend in the restoration industry, the more you begin to understand what chemicals perform the specific work you need performed (e.g. disinfection). You also understand what chemicals can perform this with minimal hazards and what chemicals require more safeguards (e.g. PPE).

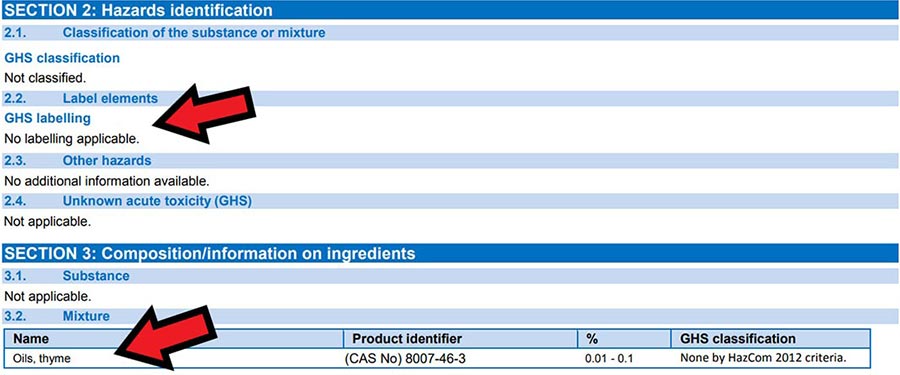

The introduction of “green” chemicals that perform as well as or better than previous, more-hazardous chemicals are perfect examples of how the ingredients list can tell an experienced user what to expect. For instance, the minimal hazards and pleasant fragrance of natural oil ingredients will appear as a big contrast to acid- or alcohol-based ingredients that have much greater hazards. See Figure 4 below that shows “No labeling applicable” for the Section 2 Pictograms and a natural oil for the Section 3 Ingredients.

From my safety perspective, it’s pretty easy to see that the more hazardous ingredients correlate with greater exposure and injury risks for the chemical users. The risk and hazards also extend to the occupants of the building the chemicals are being used in. So, having the ingredients listed in all SDSs becomes a very powerful piece of information!

Your SDS Collection

Now, let’s switch gears and talk about collecting and managing your chemical user manuals. As you’re likely aware, OSHA requires employers to have an SDS for every chemical that an employee may be exposed to.6 The exposure could be at job sites, warehouses, storage areas, or even office closets in the case of common cleaners.

Note: I want to clarify my use of the word “chemical.” OSHA defines a chemical as any substance or mixtures of substances. So technically speaking, a “chemical” can be a liquid, solid or a gas.7

Employers will need to collect, organize and make SDSs readily accessible to employees. Options for collecting SDSs include printed or electronic copies.8 Employers can get an SDS from their chemical supplier or look them up on the manufacturer’s website. When they are all collected, create a list of the chemicals, which is commonly called a chemical inventory.9

Now is when an employer will need to decide how to manage the SDS collection. The choices I most commonly see are:

- Electronic SDS collection

- Binder of printed SDSs

- Combination of the two; for example, electronic at the office, binders in the trucks/vans

All three of these choices can work and are OSHA complaint. Again, OSHA requires SDSs to be readily accessible. I’ll add an observation from experience: Electronic SDS collections are much easier to update than printed SDSs in binders!

Training

I’ll wrap up with training employees. OSHA requires employers to provide employees with “…effective information and training on hazardous chemicals in their work area.” This is typically called “Hazardous Communication” or HazComm training. It needs to be done when employees are first assigned to work with chemicals, or when new chemicals are introduced.10

Note that HazComm training for employees will need to be more extensive than this column; this just serves as an introduction to some of the important parts of an SDS. I recommend restoration companies look at 1910.1200(h)(1) for the specific training requirements or download the “OSHA Hazard Communication Small Entity Compliance Guide for Employers That Use Hazardous Chemicals.”11

Conclusion

I hope this information will help your restoration company better understand chemical hazards and safety. I truly believe that SDSs can and should function as the user manual for chemicals. The restoration industry uses chemicals on a daily basis, so it is critical that we use them safely!

For more information, feel free to reach out to me, your regional OSHA Office, or use the references below. Have a safe and successful day!

References:

- 29 CFR 1910.1200(a)(1)

- 29 CFR 1910.1200(g)(2)

- OSHA 3491-01R 2016, “OSHA Quick Card, Hazard Communication Standard Pictogram”

- Thermo Fisher Scientific Sodium Hypochlorite SDS, Revision date 01-Apr-2021, Revision Number 8

- Benefect Botanical Decon 30 Disinfectant SDS, Revision date 10/08/2020, Version 2.7

- 29 CFR 1910.1200(g)(1)

- 29 CFR 1910.1200(c)

- 29 CFR 1910.1200(g)(8)

- 29 CFR 1910.1200(e)(1)(i)

- 29 CFR 1910.1200(h)(1)

- OSHA 3695-02 2014, “OSHA Hazard Communication Small Entity Compliance Guide for Employers That Use Hazardous Chemicals”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!