Safety Insight: Choosing and Applying the Right Fall Protection for The Job

Photo credit: welcomia / iStock / Getty Images Plus via Getty Images

A Restoration Technician never really gets to a height where fall protection is needed, right? Maybe you go up on a roof or two over the course of a year to put a tarp over it. Maybe you go up some stairs without railings in the occasional new construction home that has a mold problem. But it’s nothing like the exposure a construction company has, so it’s really no big deal, right?

Well actually no – it is a big deal. One slip, one stumble, one loss of balance and the consequences are deadly. The construction guys are exposed frequently, but most of them rarely take the risk of not having fall protection. And for good reason. Falls are the number one killer in construction. (1) The construction industry knows that and most companies don’t allow a chance for tragedy to strike. And restoration companies shouldn’t either!

In this article I’m going to explain the OSHA fall protection requirements, show you some choices and solutions for the Restoration Industry, and identify training needs. As always, I have resources for you to use at the end of the article. Let’s get started.

OSHA: Duty to have Fall Protection

As always, prior to jumping into observations and solutions let me lay out what OSHA expects from any company. First is the trigger height for fall protection. For restoration work, OSHA’s 1926 construction standard applies – 1926.501 defines the duty to have fall protection. For this, anytime an employee’s feet are at 6 feet above a lower level. More specifically, OSHA identifies the below situations as requiring fall protection when an employee is exposed to a fall of 6 feet or more (2):

- Leading or open edges

- Walking or working surfaces

- Hoist areas

- Holes

- Formwork and reinforcing steel

- Ramps, runways, and walkways

- Excavations

- Over dangerous equipment

- Bricklaying and related work

- Roofs – low slope and steep slope

- Precast concrete erection

- Residential construction

- Wall openings

Choices for Applying Fall Protection

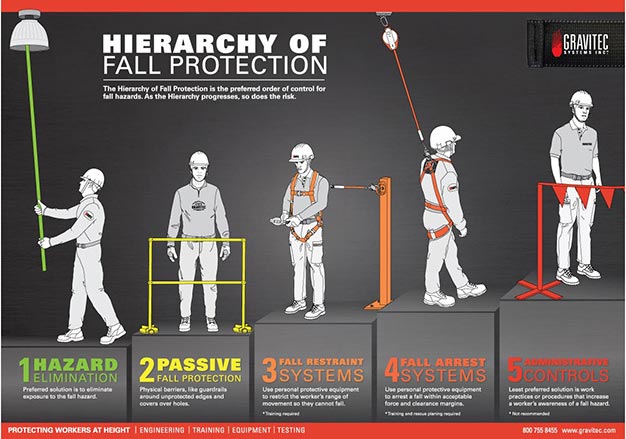

Another topic that needs to be explained initially is choosing the right fall protection. Please remember that the classic lanyard and harness are not always the solution! A lanyard and harness are actually the last solution for protecting a restoration technician. There are a few solutions that are actually easier and safer.

Fall Hazard Elimination

This is very simple – try to do the work from the ground. By doing the work from the ground, you eliminate the chance of a fall. For instance, maybe you could use some type of extendable pole to reach and perform the work.

Passive Fall Protection

This entails installing a guardrail around the exposed edge. Remember that the guardrail includes a top rail, middle rail, and toe kick. (3) This can be job-built or installed as a rented/purchased system. The beauty of this is that once it’s up, there is basically nothing else that needs to be done.

Fall Restraint System

This entails the use of a limited length or adjustable lanyard, along with an anchor point and body harness, that only allows a worker to reach the exposed edge, but not fall over the edge. This is the preferred system by many companies if guardrails are not feasible. The preference lies in the fact that if adjusted properly, a worker will never fall over an edge. That greatly reduces the chance of injury, hanging suspended by a harness, and the need for rescue!

Fall Arrest System

This is the classic anchor, lanyard, and body harness that everyone is familiar with. It is different than the Fall Restraint because the worker can actually fall over the edge. The harness and lanyard will arrest that fall; however, you are still left with the possibility of the worker striking something during the fall, swinging into an object, and the need for rescue. Obviously, this is all better than an employee’s fall not being arrested and landing on the ground.

Administrative Controls/Flagging & Monitor

This entails the use of stands, rope with flags installed around the perimeter of a roof, and a monitor to observe and warn workers when they get close to the edge. It is only for low-slope or flat roofs and is primarily used by roofers and the service industry (e.g. a/c unit services).

Pro tip on choices for fall protection – there are an infinite variety of types of fall protection. Every year I see something new that provides a unique solution. It’s almost impossible to keep up with the selection and variety, so I always recommend establishing a relationship with a manufacturer’s representative whose job is to keep up with all the new and different choices.

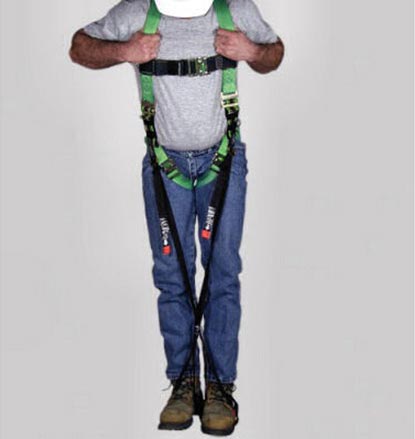

One example is an item now routinely included with a fall protection harness – Rescue Straps (see right). If a worker falls, these straps can be released from a pouch and allow the worker to stand in them and relieve pressure from the harness that can stop blood flow to the legs.

Fall Exposure and Solutions for Restoration Techs

Unprotected Interior/Exterior Edges

Sometimes the interiors of buildings are unfinished or have been damaged by fire. That can leave open and exposed edges, like stairs and balconies. Techs must be protected from falls before beginning their work in these locations. I typically see railings built in-place with 2x4’s along these edges. There are also companies that sell pre-made railings that can be placed into brackets that are attached to the edge. Otherwise, you will likely need to install an anchor back away from the edge and have techs in harnesses and lanyards.

Scaffolds

Part of the beauty of scaffolds is that the fall protection is already built-in in the form of railings. That provides a convenient solution. However, there can be challenges on where scaffolds can be built, how long it takes to get an installer to the job, and cost considerations. There are also training requirements for the person building the scaffold and the techs that will be working on the scaffold. Be sure to get training and follow the OSHA 1926 Subpart L standard for scaffolds. (4)

Aerial lifts

Aerial lifts, like scissor lifts and boom lifts, can provide a quicker and easier alternative to scaffolds. They can obviously be moved around and may work in areas where a scaffold is not practical. Scissor lifts are particularly handy in building interiors. Boom lifts are great for access to exterior walls and even for roof tarping. Be sure to get training and follow the OSHA 1926.453 standard for scaffolds. (5)

Roof tarping

As part of the response to a fire- or wind-damaged building, I have seen Restoration Companies install tarps on damage roofs. This is possibly one of most dangerous tasks a Restoration Tech can perform. The biggest risk is a fall into or off a building while installing the tarp. Winds can make handling the tarp equally dangerous. This is all compounded by a lack of points to tie a fall protection harness to on most roofs. Which leads us to the safest method; installing the tarp without getting on the roof. The choices for this method will vary based on the roof configuration; they include installation from the ground, from a ladder, or from a lift.

Training

As mentioned previously, OSHA expects employees working at height to be trained. There are many options for getting that training, including online training. However, in this case my experience has shown that in-person training is the best for fall protection. In-person can allow:

- Demonstration of how to put on and adjust a harness

- How to connect to anchor points

- How to find or install an anchor point

- How to setup the correct length of a lanyard

Remember there is always the option of having one trained competent fall protection person for the company who can cross-train other employees!

Whoever ends up training employees, be sure the training meets the requirements of 29 CFR 1926.503, it is documented and retained. (6)

Conclusion

Restoration techs do have exposure to falls at times. However, the risk isn’t consistently identified or properly addressed, possibly because techs don’t have the day-to-day exposure that some construction workers have. However, the potential injuries due to a fall are very severe. In the past, I had a VP of Safety remind me that breathing in some of our respiratory hazards can be bad, but the fall from height can be fatal. I don’t want to downplay other hazards in our industry, but he is right, one fall can be devastating. Make sure you keep that perspective as you evaluate future restoration work!

Resources

Occupational Safety and Health Administration, OSHA Fact Sheet, Reducing Falls during Residential Construction: Working in Attics, DOC FS-3553, 05/2012. https://www.osha.gov/sites/default/files/publications/working-in-attics-factsheet.pdf

Occupational Safety and Health Administration, OSHA Fact Sheet, Reducing Falls during Residential Construction: Roof Repair, DOC FS-3479 9/2011. https://www.osha.gov/sites/default/files/publications/reducing-falls-roof-repair-factsheet.pdf

Occupational Safety and Health Administration, Fall Protection in Construction, OSHA 3146-05R 2015. https://www.osha.gov/sites/default/files/publications/OSHA3146.pdf

Occupational Safety and Health Administration, OSHA Fact Sheet, Aerial Lifts, DSG 4/2011. https://www.osha.gov/sites/default/files/publications/aerial-lifts-factsheet.pdf

Occupational Safety and Health Administration, OSHA Fact Sheet, Tube and Coupler Scaffolds – Erection and Use, DOC FS-3759 11/2014. https://www.osha.gov/sites/default/files/publications/OSHA_FS-3759.pdf

References

(1) Centers for Disease Control and Prevention, The National Institute for Occupational Safety and Health, Campaign to Prevent Falls in Construction. https://www.cdc.gov/niosh/construction/stopfalls.html

(2) 29 CFR 1926.501 https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.501

(3) 29 CFR 1926.502(b) https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.502

(4) 29 CFR 1926.450-454. https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.450

(5) 29 CFR 1926.453. https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.453

(6) 29 CFR 1926.503 https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.503

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!