What Does EPA Registration Really Mean?

Perhaps it is time for chemical manufacturers to show real-world testing.

Untreated raw sewage in a 5-gallon bucket was retrieved from the Kalamazoo Water Reclamation Plant and used in the evaluation of the effectiveness of Benefect Atomic Degreaser and Decon 30 botanical cleaning and disinfection solutions. Photos courtesy of Wonder Makers Environmental.

The bucket of sewage was transported to the Wonder Makers Environmental facility where it was used to contaminate various simulated building surfaces. Photos courtesy of Wonder Makers Environmental.

A simulated wooden wall assembly, concrete floor, and concrete wall were contaminated with the untreated sewage in an out-of-doors parking area at the Wonder Makers Environmental facility. Photos courtesy of Wonder Makers Environmental.

Simulated vertical wood stud surfaces, horizontal wood stud surfaces, horizontal wood sill plate surfaces, vertical OSB sheathing surfaces, horizontal concrete surfaces, and vertical concrete surfaces were contaminated with raw sewage. Sponge samples were collected from the contaminated surfaces. Photos courtesy of Wonder Makers Environmental.

Following sponge sampling, the contaminated surfaces were sprayed with a diluted mixture of Atomic Degreaser using a FOAM-iT sprayer. Photos courtesy of Wonder Makers Environmental.

Following application of Atomic Degreaser, the surfaces were cleaned with disposable towels. Then Decon 30 was sprayed on the surfaces using the FOAM-iT sprayer. Photos courtesy of Wonder Makers Environmental.

Have you ever seen the marketing information for products being sold to the restoration industry and wondered to yourself, “Is all this stuff true, that they’re saying?” Being an instructor for a number of courses related to forensic restoration, mold remediation, and infection control, my skeptical nature sometimes gets the best of me. When I read marketing and sales literature, especially for chemicals, I usually take the attitude made famous in the state of Missouri: Show me.

EPA Registration: What Does It Really Mean?

Most chemicals sold as disinfectants to the restoration industry tout their EPA registration number. Make no mistake, this is a critical piece of data in deciding if a contractor should use that product for such hazardous situations as sewage clean-ups, bat or bird infestations, mold remediation, or blood borne pathogens associated with forensic restoration. But I believe we may be putting our crew members, our clients, and our business at risk if we blithely accept that having a registration number is enough to ensure effectiveness.

Nor am I alone in this thinking. Normally, a test for the registration of a new disinfectant involves measuring the kill ratio on a stainless steel surface. This process is so far removed from real world situations that in 1990 the General Accounting Office investigated and concluded that “evidence from EPA, the states, and others suggests that up to 20 percent of disinfectants on the market may be ineffective”. (See Disinfectants - EPA Lacks Assurance They Work; United States General Accounting Office; report to Congressional requesters; August 1990.)

Think about that for a minute. Over 15 years ago, our government had data suggesting one out of every five products sold as a disinfectant may not actually work. This makes perfect sense when a person understands just a bit about the EPA testing process and the realities of the restoration world. I have investigated and monitored thousands of clean-up projects over a 30+ year career. Rarely have smooth stainless steel surfaces been even a fraction of the surfaces needing to be cleaned after a water loss, mold remediation, or disease outbreak. In contrast, walls, flooring, and building components are the items typically cleaned on site after some sort of loss that is addressed by restoration professionals.

A Different Approach to Testing

So, when I saw another advertisement for a disinfectant for the restoration industry, I developed an idea for a simple process to go beyond the EPA testing requirements for disinfectants. Since the EPA tests do not represent real-world usage of the product, create one that does! As such, a study was designed to replicate a real-life loss: a sewage backflow in a basement with a cement floor and wood studs. Rather than do it as a case study and have to rush out to a Category 3 water loss on short notice and try to adapt a study to the specific conditions, a different approach was used. To avoid the emergency nature of a real water loss and ensure a worst-case scenario in regards to contamination, a process was developed to simulate real-world conditions. Another benefit of this approach is that the detailed testing methodology and detailed controls allow others to replicate the test and validate the results.

The design of the test process focused on three of the most common questions asked about chemicals used to assist restoration work. Specifically, a process was developed that would help answer:

- How do the chemicals perform when cleaning sewage from unfinished wood-framed assemblies?

- How do the chemicals perform when cleaning sewage from concrete surfaces?

- How do the chemicals perform based on the orientation of the surfaces (vertical or horizontal)?

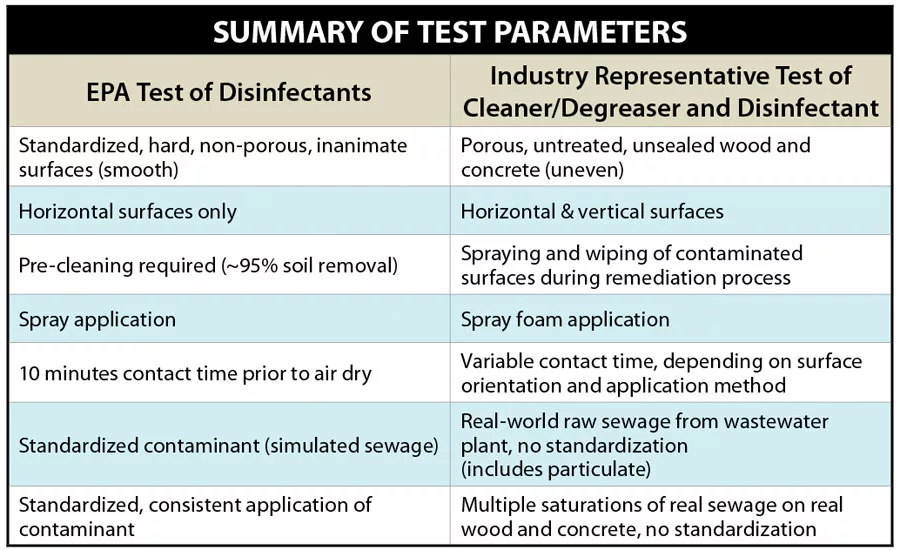

As an additional control on the validity of the results, the test created conditions to determine how the products would perform under a worst-case scenario (i.e., raw, undiluted sewage as the test agent). Since disinfectant manufacturers specify that surfaces be cleaned prior to disinfecting, that step was also built into the process. The first table above summarizes the distinctions between the standard test parameters for chemical registration purposes in the United States and Canada and those utilized for this evaluation of the a disinfectant.

Finding a Sponsor

Some people contend that the only true science comes from unbiased research conducted in academia with government funds. While this may sound like the ideal approach, it ignores the reality of experiments which are conducted by people; the truth is that everyone has biases. The key to good science is to make sure that potential biases are revealed and accounted for in the report. As such, Wonder Makers looked for a research sponsor for this experiment who was interested in an objective review of the effectiveness of a disinfectant in real world conditions.

Benefect was intrigued by the concept. With the goal of producing solid results, whatever those results revealed, Wonder Makers Environmental used the test design and conducted experiments. Two botanical products, Benefect Atomic Degreaser and Benefect Decon 30, were utilized in the test process.

Fascinating Results

The combined test results are very informative, with a number of clear trends revealed by a simple review. Overall, a near total reduction in biological contamination was observed after cleaning with and application of the disinfectant.

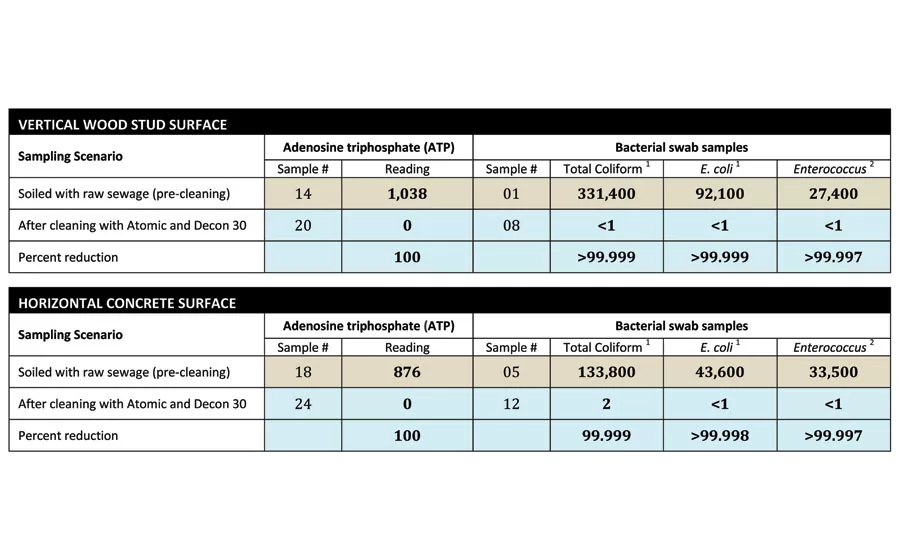

The ATP meter and swabs measurements indicated complete reductions in contamination levels. ATP levels were reduced to zero on the four wood surfaces and the two concrete surfaces after cleaning and foaming with the disinfectant. These reductions were observed regardless of whether the surface was vertical or horizontal.

Specifically, ATP readings on the vertical and horizontal wood stud surfaces were 1,038 and 1,203 relative light units (RLU) before cleaning. After cleaning, the ATP readings were zero. On the vertical OSB sheathing surface and horizontal wood sill plate surface ATP readings were 980 and 1,137 RLU before cleaning. After cleaning, the ATP readings were zero. For ATP readings on the horizontal and the vertical concrete surfaces the pre-cleaning results were 1,309 and 876 RLU prior to the start of the prescribed cleaning process. After cleaning, the ATP readings were zero. In all these cases the field measurements of overall biological cleanliness using adenosine triphosphate technology as a measurement showed 100% decrease in contamination. In layperson’s terms, the cleaning and sanitizing of the real life surfaces using foamed-on restoration products eliminated the severe black water contaminants.

Given that ATP measurements are general in nature rather than organism specific, side-by-side pre-cleaning and post-cleaning samples were collected to identify representative bacteria types. The second sample results chart above shows that total coliform levels were reduced by greater than 99.99%—a minimum 4-log reduction of microbial contaminants. For the more dangerous E. coli bacteria, levels were reduced below the laboratory’s ability to measure the organism—essentially a 100% reduction1. In similar fashion, the Enterococcus levels were reduced below the laboratory’s ability to measure the bacteria.

Conclusions

The goal of the study was to answer three questions about the effectiveness of using a cleaner and antimicrobial under real world conditions rather than laboratory test conditions. Specifically, the research was designed to determine how such chemicals perform when cleaning sewage from unfinished wood-framed assemblies and concrete surfaces that are both vertical and horizontal. In that respect, the study provided solid data to answer the questions that framed the study design. The high level of bacteria reduction with minimal cleaning effort should give restoration contractors confidence that they can deal with black water flooding of wooden sill plates, structural components, and even concrete, in an efficient manner.

In addition to providing answers to common restoration industry questions, it is hoped that such tests will encourage other interested parties and manufacturers to expand their research efforts. Other experiments using this test design would create a larger database of comparative information that could be utilized by restoration professionals to make decisions about the best products and processes to use to address black water losses.

Endnotes

1. Scientists are loathe to use the terms “100% reduction” or “eliminated” because there is never total assurance that the analytical method can recover or detect all of the micro-organisms. However, from a practical perspective, a result that is below the detection limit (sometimes reported as “below the method detection limit” or BMDL) is the same as a 100% reduction as long as the process has a very low limit of detection.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!