Blast It! Breaking Down the Types of Media Blasting

Understanding when to use baking soda, sand, dry ice, or other media depending on the surface

Evidence of a fire is blasted away with baking soda.

Soda blasting was used to blast away the paint on this ornamental brass outside a police station. Baking soda was chosen because other harsher media may have damaged the brass.

Soda blasting was used to remove the paint hiding the beautiful brink on this home.

Sand or grit media like crushed glass can work well to clean surfaces like all these wood beams.

Glass bead media is a good option for projects like these stainless steel tanks because it creates a good, uniform result on the thin metal while being less abrasive than crushed glass.

Sponge jet was an alternative blast media on the restoration of the Kansas State Capital building because the original spec called for baking soda, which created too much dust and exposure was a growing concern.

A vapor blast system with coal slag was used on the basement’s stone walls to remove the existing paint and restore the original stone surface.

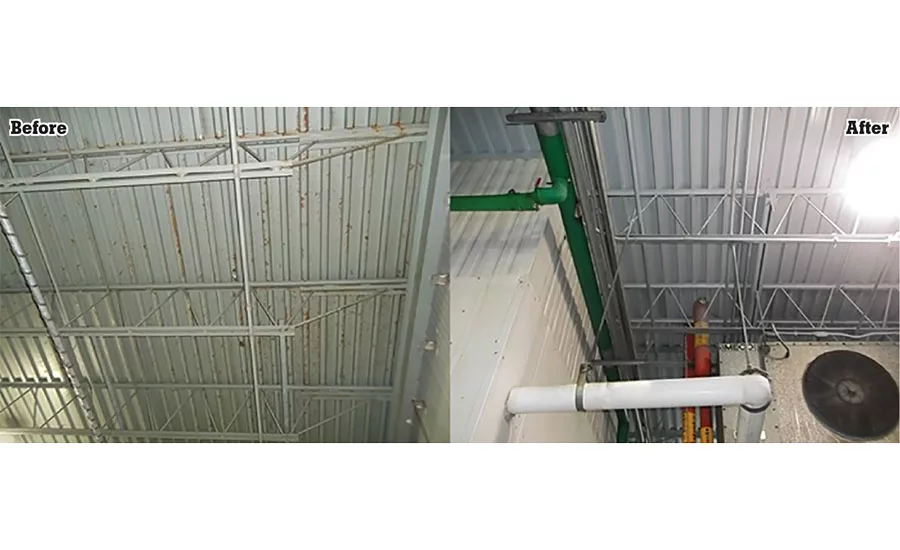

Check out how well dry ice blasted away the rust on this metal ceiling.

It is critical when using certain media to utilize proper containment protocols in the areas where you’re blasting to be sure particles, debris and dust are contained and do not contaminate other areas.

Media blasting. It’s a term with many meanings: demolition by dynamite; criticism of major news networks for their ethics; or restoration work. Media blasting in restoration has a variety of uses from blasting away fire damage to deodorizing and cleaning a surface. Each requires unique surface preparation, cleaning, and stripping.

It is important to understand the different advantages and disadvantages of media types. Grit medias can offer great cutting and stripping abilities, whereas a bead media can offer better polish and surface consistency.

Baking Soda

Baking soda has been a staple in the media blasting world since it was used to clean the Statue of Liberty in the 1980s. Baking soda acts as an air or refrigerator freshener as a household item, and as a blast media the same concept holds true. In blasting, we have found baking soda works great as a deodorizer and cleaner and therefore a natural fit for work such as fire restoration. The substance will not only clean wood joists, concrete walls, and brick surfaces, but will also deodorize the smoke smell to further restore the surface to its original state.

Baking soda can also strip and prep surfaces that are thin, ornamental or delicate because it is much less abrasive than a traditional sand or grit media. For instance, on the previous page, you saw the brass police station entryway, where the original brass was painted many years ago and needed to be restored. A traditional sand or grit media could have damaged the brass and the existing windows around the surrounding entryway. Therefore, baking soda was selected as the media of choice.

Due to the acidic nature of baking soda, one potential drawback to blasting with dry baking soda is it can and will kill any vegetation in an outside environment. Therefore, the time of year is important if using baking soda outdoors.

Sand & Grit

Traditional sand or grit media are still used in some surface preparation or stripping applications. Sand or grit media such as crushed glass are proficient at removing years of buildup, paint, and corrosion from surfaces such as wood ceilings, like the image below, concrete statues, or brick walls. From removing stain or varnish from wood ceilings, restoring stone walls and paint removal, grit medias are capable of cleaning the surface to leave it natural and maintenance-free or to prep the surface for coating.

Glass Bead

Glass bead is a blast material often used on surfaces such as stainless steel, brass, or bronze to remove weld slag, buildup, or brighten the existing surface before sealing. Glass bead is less abrasive than the traditional grit media. The material is a bead shape instead of a grit shape, therefore the round edges are better at creating a uniform finish on ornamental, delicate, and thin metal surfaces, without the abrasive cutting ability that a grit or crushed glass media provides.

Vapor & Water

What happens if a project calls for a cleaning or surface preparation process with little or no dust? Some low-dust or no-dust blasting mediums include vapor or wet sandblasting, sponge jet blasting and even dry ice cleaning. Sponge jet blasting is used with small sponge particles that act to absorb the surface contaminant, such as paint or buildup, and remove it from the surface as the sponge particles expand. Sponge jet blasting also offers the ability to recycle the material. Granted, with any reclamation system virtually any dry blast media can be recycled. Sponge jet was an alternative blast media on the restoration of the Kansas State Capital building because the original specs called for baking soda, which created too much dust and exposure was a growing concern.

Vapor or water blasting involves using a water stream, such as a water induction nozzle added at the trigger of the blast hose, in additional to a typically dry blast material. Several blast equipment manufacturers have developed wet blast pots. Those systems add water into the blast pot directly so the blast steam is a mixture of water and blast materials such as baking soda, glass bead, crushed glass, etc. The advantage to this system is the low dust, water vapor is emitted instead of dust, and due to the use of water there is significantly less blast material used in the stripping and cleaning process. We completed a project in a home using a vapor blast system with coal slag on the basement’s stone walls to remove the existing paint and restore the original stone surface. Vapor blasting limited dust exposure to the rest of the house.

Dry Ice

Dry ice blasting involves either pelleted CO2 pellets or shaved block CO2 as the blasting media. The process works to clean or remove flaking, failing paint from a surface to prep it for new paint. Dry ice is effective at removing soot and char from wood beams, joists, and trusses damaged by a fire; however, it is not as effective at removing the smoke odor as baking soda. Dry ice often used in fire restoration scenarios when the residence or building is occupied because it created significantly less dust than traditional dry blasting. Upon contact, the dry ice material will evaporate leaving only the waste contaminant. This process can often reduce the amount of clean up time on a project. Dry ice is also used in plant environments because there is no contamination of secondary media waste.

Containment

Dust is often a factor whenever any dry media blasting is taking place, therefore some projects require containment or dust control measures to limit dust exposure to outside areas. If performing a renovation on a single room or basement in a home for example, dust most often needs to be contained to that one area so it does not migrate to other areas of the home especially if the residence is still occupied.

Whatever the problem, situation, or desired result from a restoration, construction, or renovation project, media blasting can offer a solution from one process or a combination of multiple processes to get to the desired outcome, surface, or appearance.

Bio:

My name is Jay Dillon, and I’m the funny guy and writer here. I am a Missouri State University Springfield graduate with a BA in English Literature, I live in Lenexa, Kan., and work out of Blast-It Clean’s fixed base operation in Kansas City, Missouri. I’m an administrator at Blast-it-Clean and awesome at basketball; my best moves seem to happen when nobody is looking.

Images courtesy of Blast-It Clean

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!