Weekly Hands-on How-To powered by KnowHow

How To Inspect PPE

Your team's safety gear is their lifeline. Imagine being halfway through an asbestos job only to see that your gloves have holes or your respirator is cracked—suddenly, a tough day on the job has turned into a dangerous one. Regular PPE inspections aren't just a formality.

Whether you're diving into a moldy basement or tearing out water-damaged drywall, having the right, well-maintained PPE can make all the difference. In this weekly how-to, powered by KnowHow, we’ll take you through the ins and outs of PPE inspections. We've got you covered, from checking your gear before you start to maintaining and storing it properly.

So, let’s get started and ensure that your PPE is always up to the task so you can focus on what you do best—restoring homes, businesses, and the lives of your clients.

Note: This Weekly Hands-On How-To was based on this template in KnowHow’s template library.

Step 1: Ensure You're Using the Right PPE

Given the variety of dangers that restoration work throws at you, selecting the correct PPE is mission-critical for keeping your team safe. From protecting eyes during demolition to ensuring clean breathing during mold remediation, each piece of equipment plays a vital role.

Here’s a look at the essential PPE types and their applications:

- Head Protection: Hard hats protect against falling or flying objects on restoration sites, such as debris from collapsed structures or dropped tools. Ensure the hard hat fits properly; too-large or too-small hard hats are ineffective and compromise safety during roof repairs or structural assessments.

- Hearing Protection: Restoration work often involves harmful noise while cutting through damaged structures, operating heavy machinery, or dehumidifiers and high-powered fans. Earmuffs and earplugs are essential in these high-noise areas to prevent occupational hearing loss.

- Skin and Hand Protection: Choose gloves suited to your specific tasks. For instance, use rubber gloves to guard against chemicals and pathogens in contaminated floodwater and cut-resistant gloves to handle broken glass, sheet metal or sharp debris.

- Respiratory Protection: Respirators safeguard against toxic substances and airborne contaminants like mold spores, asbestos, and cleaning fumes. Ensure a snug fit to protect against dust and chemical vapors during tasks like sanding drywall, spraying disinfectants, or working in mold-infested areas.

Always confirm you're using OSHA-regulated PPE for the job by checking their guidelines at OSHA. And for a full breakdown of how to properly don and doff full PPE, check out our comprehensive guide here.

Step 2: Maintain and Store PPE Properly

Proper maintenance and storage of PPE extend its life and effectiveness. Most PPE should be stored at room temperature, away from chemicals, UV light, and moisture. These elements, along with abrasion, snags, and grime, accelerate the aging process of safety equipment.

Following these basic rules of maintenance and storage will help you extend the life of your PPE and make it easier to spot defects when they appear:

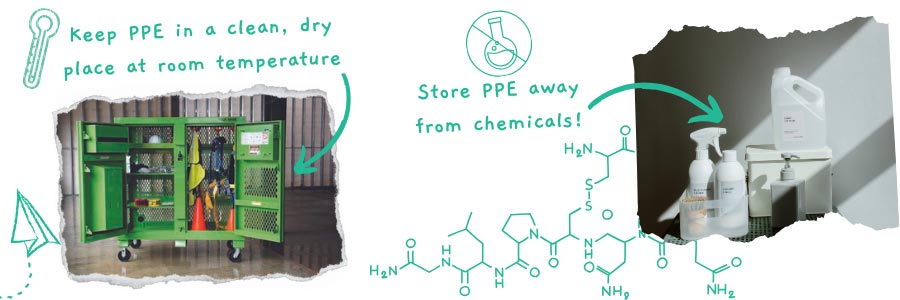

- Storage Conditions: Keep PPE in a clean, dry place at room temperature. Avoid areas exposed to direct sunlight, chemicals, or extreme temperatures, as these conditions can degrade the materials.

- Protection from Contaminants: Store PPE away from potential contaminants, such as oils, solvents, and other chemicals, that might compromise the safety of the equipment.

- Regular Cleaning: Clean PPE according to the manufacturer’s guidelines. For example, wash gloves and goggles with mild soap and water and sanitize your respirators regularly.

- Organized Storage: To avoid any damage that could occur during storage, use designated storage areas such as PPE lockers or cabinets. Keep items organized and easily accessible, avoiding piled-up items or cramming items into tight spaces.

Step 3: Evaluate Every Piece Individually

Different types of PPE require specific inspection procedures. Once you've confirmed that you're using the right equipment, ensure you perform the appropriate inspections for each type.

Key points to check for each piece of equipment include:

- Eye and Face Protection: Check for scratches, cracks, or any damage to the lenses and frames. Ensure that straps are intact and not stretched out. Verify that any adjustable parts function correctly.

- Head Protection: Inspect hard hats for dents, cracks, and signs of brittleness. Ensure the suspension system inside the hat is not damaged and fits securely.

- Hearing Protection: Examine earmuffs for cracks or wear in the cushions. Ensure earplugs are clean and free from tears. Replace disposable earplugs regularly.

- Skin and Hand Protection: Look for holes, tears, or thinning in gloves. Ensure that gloves fit snugly and are not worn out. For specialized gloves, like those resistant to cuts or chemicals, confirm that the protective coatings are intact.

- Respiratory Protection: Inspect respirators for cracks, tears, and the integrity of the filter. Check the straps and seals to ensure they are not stretched or damaged. Make sure the respirator fits snugly on the face without any air leaks.

By performing these detailed inspections, you can identify issues early and replace or repair PPE as needed. This ensures all protective gear is effective, compliant with safety standards, and ready to protect you and your team.

Conclusion

Regular inspections, proper maintenance, and correct usage can significantly reduce risks and enhance job site safety. Following the steps outlined in this guide each time you arrive on site will help ensure that every piece of equipment your team uses is up to the task.

But mastering PPE inspections and overall safety practices goes beyond just following instructions—it's about integrating this knowledge into your daily operations to maintain consistently high standards. With KnowHow, it's never been easier to provide your team with the real-time guidance, training, and support (in their native language!) they need to handle every challenge confidently and competently.

Empower your workforce and elevate your safety standards with KnowHow. Visit tryknowhow.com to discover how we can support your team's success and safety in the field.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!