Lead-Based Paint Regulations & How They Impact Your Restoration Project

Photo: yanik88 / iStock / Getty Images Plus via Getty Images

Projects that involve damage or disturbance of painted or coated surfaces, as well as development or improvements of existing structures, may involve some level of lead impact regardless of the type, age, or location of the property. The use of lead in paints and coatings has not been completely banned in the United States, and elevated blood lead concentrations in children and adult workers resulting in adverse health effects is still an issue today. Federal, state, and local regulations are in place and continue to be updated to reduce human exposure to lead.

The United States Environmental Protection Agency (EPA) and the United States Department of Housing and Urban Development (HUD) developed standards and guidelines to eliminate lead-based paint hazards and prevent childhood lead poisoning. These standards and guidelines were implemented after Congress reported in 1992 that low-level lead poisoning was afflicting as many as 3,000,000 children under the age of 6, mainly as a result of ingestion of household dust containing lead.1 To further eliminate potential childhood lead exposure, the EPA and HUD recently adopted new standards that reduce the allowable concentrations of lead in dust.

These regulatory changes are applicable to projects that require the removal of lead-based paint or a lead-based paint hazard, i.e., abatement projects. These changes are not applicable to most renovation or restoration projects. Regulations are in place to protect occupants and workers from lead exposure during these activities. Understanding the implication of applicable and current regulations is essential for a successful project to ensure regulatory compliance, to limit liability, to eliminate the potential of creating lead hazards, and to understand how compliance can impact project timelines and costs.

How is Lead Regulated?

Prior to the start of any project, there must be a clear understanding of potential environmental hazards impacting the property and the regulatory compliance requirements to address them. Lead is one commonly encountered environmental hazard. Regulatory compliance is required for most projects to address occupational and/or childhood exposure to lead and lead-based paint.

Occupational Exposure

It is a regulatory requirement to protect employees from occupational exposure to lead. This is true on every project and in any setting, whether the property is residential, commercial, public, or industrial. The Occupational Safety and Health Administration (OSHA) and state-specific programs are in place to protect workers from exposure to lead in a variety of forms, not just in lead-based paint. The requirements to implement specific regulatory compliance activities are triggered when workers are exposed to lead above established standards, as confirmed through air monitoring. Regulatory compliance is the contractor’s responsibility—as the employer to the employee—and is factored into work requirements and project costs.

Childhood Exposure

Regulatory requirements to reduce or prevent childhood exposure to lead are in place for residential properties and child-occupied facilities constructed prior to 1978. There are two different project intents that trigger these regulations: renovation and restoration, and abatement. The difference between these two criteria is mainly the focus of the work being performed. Renovation or restoration occurs regardless of the presence of lead-based paint, while abatement is intended to permanently eliminate lead-based paint or lead-based paint hazards. The more likely of these scenarios, for property loss claims and development and improvements, is renovation and restoration.

What Is Lead-Based Paint?

Lead-based paint is defined as “…paint or other surface coatings that contain lead equal to or exceeding 1.0 milligrams per square centimeter or 0.5 percent by weight or 5,000 parts per million (ppm) by weight.” One common misunderstanding is that properties constructed after 1978 are “lead free.” This idea comes from the fact that the Consumer Product Safety Commission (CPSC) reduced the amount of lead allowed in residential paint in 1978; however, these paints can still contain some concentrations of lead.2

What Properties Trigger Regulatory Compliance for Childhood Exposure to Lead?

Regulations for childhood lead exposure are in place for two types of properties constructed prior to 1978:

-

Child-Occupied Facility

The definition of a child-occupied facility applies to multiple settings that are not always simple to understand. The EPA defines a child-occupied facility as “…a building, or portion of a building, constructed prior to 1978, visited regularly by the same child, under 6 years of age…” and can include day care centers, preschools, and kindergarten classrooms, among others. A child-occupied facility may be located in target housing, or in public or commercial buildings, and can include common areas such as restrooms and cafeterias.3 -

Target Housing

This is defined by the EPA as “…any housing constructed prior to 1978, except housing for the elderly or persons with disabilities (unless any child who is less than 6 years of age resides or is expected to reside in such housing) or any 0-bedroom dwelling.”3 A loft with the same living and sleeping area is an example of a 0-bedroom dwelling. Target housing includes any residential property that meets the EPA’s definition. Hotel suites with separate sleeping and living areas are regulated for renovation and restoration because they are not a “0-bedroom dwelling.”4

What Materials Trigger Regulatory Compliance for Childhood Exposure to Lead?

Once you’ve identified that the property is target housing or a child-occupied facility, determine regulatory applicability based on the presence of lead-based paint or lead-based paint hazards.

Got Lead-Based Paint?

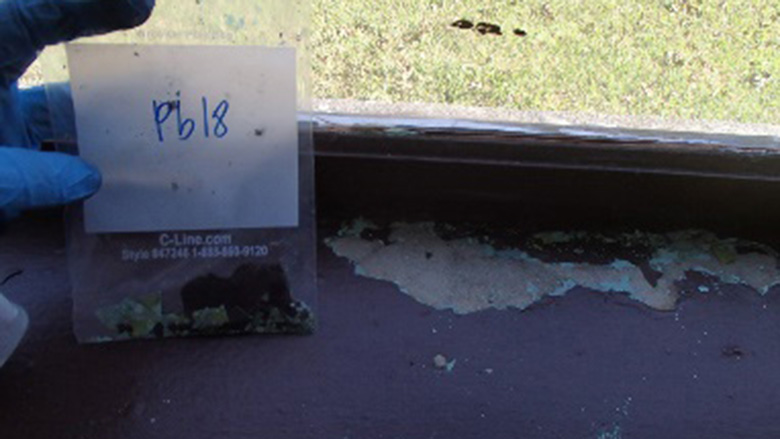

For both renovation and abatement projects, lead-based paint is either assumed present or is identified through a lead-based paint inspection (a surface-by-surface investigation for lead-based paint). These inspections are performed by a Certified Inspector (Inspector) or Certified Risk Assessor (Risk Assessor) utilizing an X-Ray Fluorescence (XRF) device or paint chip sampling (see figures).

Inspectors or Risk Assessors are accredited under state or federal regulations, which may require training classes, licensing exams, and regular re-certification. The EPA Renovation Repair and Painting Rule (RRP Rule) also allows for an EPA-Certified Renovator (Renovator) to test painted surfaces using one of the methods described above or by using an EPA-recognized lead test kit. This is not recommended, as there are limitations to the kits.5 If no lead-based paint is identified, work activities for both renovation and abatement projects are not regulated.

Got a Lead Hazard?

Most property loss claims, or development and improvement projects, will not include lead-based paint hazards. For projects that do, a lead risk assessment is required. This can only be performed by a Risk Assessor. According to the EPA, “A risk assessment is an on-site investigation to determine the presence, type, severity, and location of lead-based paint hazards (including lead hazards in paint, dust, and soil) and provides suggested ways to control them.”6 Lead-based paint hazards can include paint-lead hazards (deteriorated lead-based paint) and dust-lead or soil-lead hazards (elevated concentrations of lead in dust and soil, respectively).

Renovation & Restoration vs. Abatement

An important next step is to clarify project intent. Mistakes are commonly made at this step that can greatly impact the project scope and costs when the difference between renovation or restoration and abatement are not fully understood. After identifying lead-based paint a plan should immediately be developed and implemented to ensure damaged lead-based paint is not made worse and that no lead-based paint hazards are created, regardless of project intent.

Renovation, Repair & Painting Program

The most common mistake we see is the assumption that the project requires abatement of lead-based paint when, in fact, the RRP Rule should be applied. Renovations and restoration activities may incidentally reduce or eliminate lead-based paint or a lead-based paint hazard, but that is not the intent of the activities. Renovation and restoration projects are regulated by the EPA under the RRP Rule (40 CFR Part 745 Subpart E – Residential Property Renovation) or through EPA-authorized state or tribal RRP programs. The RRP Rule is in place for two main reasons: to ensure that owners and occupants of regulated properties receive information regarding lead-based paint hazards prior to renovation or restoration activities; and to ensure workers are properly trained, contractors are properly certified, and certain work practice standards are followed.

Lead-Based Paint Abatement

Another common mistake is assuming that lead-based paint must be abated simply because it exists. Projects with the intent to permanently eliminate lead-based paint or lead-based paint hazards are regulated by the EPA (40 CFR Part 745 Subpart D – Lead-Based Paint Hazards and Subpart L – Lead-Based Paint Activities) or by state, territory, or tribal lead regulations. These lead-based paint regulations do not require abatement of lead-based paint or corrective actions. However, these regulations are in place to ensure that if lead-based paint activities and corrective actions occur, they are performed by accredited and trained individuals with accredited and licensed contractors, following specific work practice standards and criteria. Lead hazards and lead clearance standards are identified within these regulations.

Lead-Based Paint Hazard Assessment & Corrective Actions

The requirements for a lead-based hazard assessment and corrective action are generally project-specific and will probably not apply to most property claim losses or development and improvements. Common triggers are property funding, tenant-based assistance, and project assistance programs. HUD (24 CFR Part 35 – Lead-Based Paint Poisoning Prevention in Certain Residential Structures) implements the requirements for lead-based paint activities and corrective action to occur in target housing that is federally owned or receiving Federal assistance and for Federal housing activities or programs; it also provides methods for the required evaluation and hazard reduction activities. Some federally funded projects and assistance programs (such as HUD-funded housing, with families receiving tenant-based assistance like Section 8, or program funding through the Community Development Block Grant program) may implement hazard or clearance standards that are more stringent than EPA or state standards, such as updating standards for porch floors. However, with recent revisions to regulations, most projects and assistance programs are in line with current regulatory standards.

Project Compliance Requirements for Childhood Lead Exposure

The next step after establishment of intent is understanding project compliance requirements.

Renovation, Repair & Painting Program

Compliance with the RRP Rule is the responsibility of the contractor and should be factored into the project timeline and costs. All work must be performed by Certified Renovation Firms (Renovation Firm) with Certified Renovators, both certified through EPA or EPA-authorized state accreditation programs. There is no EPA certification for workers, but training is required. General contractors on projects must also be certified. One exception to the RRP Rule is called “Minor Repair and Maintenance Activities.” This means work activities are exempt from the EPA RRP Rule if they disturb six (6) square feet or less of interior paint per room or twenty (20) square feet or less of exterior paint and do not involve window replacement or demolition of painted surface areas. An example might be electrical or plumbing work.

Compliance with the RRP Rule typically includes information distribution and notification requirements, proper work-practices, and recordkeeping and reporting requirements, among others. A project design prepared by a third-party consultant is not required under the EPA RRP Rule but is always recommended by J.S. Held. Cleaning verification is required to confirm that work is complete under the EPA RRP rule. However, if requested by the client or required due to specific funding, dust wipe clearance sampling with laboratory analysis must be performed by an accredited Risk Assessor or Inspector, or by a Certified Dust Sampling Technician. Two project examples following the RRP Rule are as follows:

-

Property Claim

A fire occurred in an apartment complex constructed prior to 1978. Impacted window frames contain lead-based paint. The window frames are removed by a Renovation Firm with a Renovator in accordance with RRP regulations, and this is followed by cleaning verification performed by the Renovator. The rest of the property is restored by a general contractor. -

Development Project

A vacant warehouse constructed in 1970 is being renovated into an apartment complex. All interior walls and doors will be removed, but columns and windows will remain. Windows, doors, and columns contain lead-based paint. The general contractor, a Renovation Firm with a Renovator, demolishes interior walls and doors, then preps and paints the remaining windows and columns in accordance with RRP regulations. Cleaning verification is performed by the Renovator after completion of renovation activities and prior to occupancy.

Abatement of Lead-Based Paint & Lead-Based Paint Hazards

The abatement of both lead-based paint and lead-based paint hazards are regulated in the same manner. Abatement is performed by a licensed Lead Abatement Contractor (Contractor), Certified Supervisors (Supervisor), and Certified Abatement Workers (Worker) in accordance with an abatement project design prepared by a Certified Project Designer (Designer) and an occupant protection work plan prepared by a Designer or Supervisor. Lead abatement clearances must be performed by an Inspector or Risk Assessor and include a visual assessment and the collection of samples for laboratory analysis. All contractors and individuals must be licensed or certified either through EPA or state accreditation programs.

The contractor is responsible for compliance with applicable EPA or state regulations (and HUD regulations, where applicable) for lead-based paint activities. Compliance requirements typically include project notification, lead-safe work practices, post-abatement clearances, and preparation of an abatement report. Two project examples where these regulations may apply are as follows:

-

Abatement

The owner of a two-unit apartment wishes to abate all lead-based paint on windows and trim. A Supervisor and Workers remove and dispose of the windows and trim in accordance with a project design and occupant protection plan developed by a Designer. An Inspector performs lead clearance sampling, which passes lead clearance standards, and the Designer prepares an abatement report. New windows and trim are installed by a window contractor. -

Development & Rehabilitation

A development company receives federal grant money to restore an abandoned 1940’s factory into residential apartments. The funding requires a risk assessment and abatement of lead-based paint hazards. Paint-lead hazards on windows and dust-lead hazards on floors by windows are identified by the Risk Assessor. A Supervisor and Workers strip and prep the windows and clean all adjacent components in accordance with a project design prepared by a Designer. The Risk Assessor performs a visual assessment and collects lead dust wipe samples, which pass lead clearance standards, and the Designer prepares an abatement report. Renovation activities throughout the rest of the property are performed by a general contractor.

New Regulatory Standards & Project Implications

The EPA and HUD have adopted new standards that further reduce the concentrations of lead in dust which were established in 2001 under the Lead-Based Paint Hazards Rule. Specifically, the dust-lead hazards standards (DLHS) were effective 180 days after January 6, 2020,7 and the dust-lead clearance levels (DLCL) were effective 180 days after March 8, 2021.8 This means that a lower concentration of lead in dust is required to determine a dust-lead hazard and to pass dust wipe clearance criteria. The EPA lowered the DLHS and the DLCL for floors and windowsills; however, they have not reduced the DLCL for window troughs because there is no DLHS standard for window troughs. A summary of the new action levels are as follows:

| Interior Floors | Windowsills | |

|---|---|---|

| Old Standard | ≥40 µg/sq. ft | ≥250 µg/sq. ft |

| New Standard | >10 µg/sq. ft | >100 µg/sq. ft |

| Interior Floors | Windowsills | Window Troughs | |

|---|---|---|---|

| Old Standard | <40 µg/sq. ft | <250 µg/sq. ft | <400 µg/sq. ft |

| New Standard | <10 µg/sq. ft | <100 µg/sq. ft | No Change |

For projects regulated under the EPA (40 CFR Part 745 Subpart D – Lead-Based Paint Hazards and Subpart L – Lead-Based Paint Activities) and HUD (24 CFR Part 35 – Lead-Based Paint Poisoning Prevention in Certain Residential Structures), the Contractor must meet tighter cleaning criteria, and the Inspector or Risk Assessor must utilize a laboratory that can meet the lower limit of detection requirements. This means that nationally- and state-accredited laboratories must meet the Laboratory Quality System Requirements (LQSR). EPA-authorized states who implement their own lead-based paint programs are required to adopt these new standards within two years of federal promulgation.

Conclusion

In summary, occupational and childhood lead exposure regulations apply to multiple projects. Therefore, it is critical that project representatives are made aware of the potential hazards of lead-based paint on their projects and that they understand the regulatory requirements by stepping through the process of determining applicability. Discussions should center around whether (“if” and “when”) the regulatory standards apply and how these regulatory requirements may impact the project from cost, time, and liability perspectives. These regulatory requirements can be as basic as occupational exposure compliance or as involved as lead-based paint hazard compliance. Most projects will typically include RRP regulations, and some will include abatement regulations due to project and property funding requirements. It is also critical that new regulatory standards are understood and correctly applied.

Acknowledgments

We would like to thank Theresa Chimento, MPH for providing insight and expertise that greatly assisted this research.

Theresa Chimento is a Vice President and Regional Lead in J.S. Held’s Environmental, Health & Safety Practice. She is an experienced environmental consultant in both the field and as a project manager. Her professional experience in environmental consulting services has included initial scope assessment and project development, initial assessments and data gathering, preparation of assessment reports and recommendations, development of remediation protocols and abatement specifications, project oversight and clearances, close-out report and final report documentation, and project management with client and contractor correspondence through the entirety of the project.

Theresa can be reached at tchimento@jsheld.com or +1 504 420 1978.

References

- U.S. Department of Housing and Urban Development. Residential Lead-Based Paint Hazard Reduction Act of 1992 – Title X. Retrieved from https://www.epa.gov/lead/residential-lead-based-paint-hazard-reduction-act-1992-title-x.

- U.S. Consumer Product Safety Commission. Lead in Paint. Retrieved from https://www.cpsc.gov/Business--Manufacturing/Business-Education/Lead/Lead-in-Paint

- Environmental Protection Agency. 40 C.F.R. Part 745 – Lead-Based Paint Poisoning Prevention in Certain Residential Structures (2019, July 9). Retrieved from https://www.ecfr.gov/cgi-bin/retrieveECFR?gp=&SID=7f4c46c32e637e0649d5fda02306e729&mc=true&n=pt40.34.745&r=PART&ty=HTML

- Environmental Protection Agency. (2018, March 22). Lead-Based Paint Program Frequent Questions. Retrieved from https://www.epa.gov/sites/production/files/2018-03/documents/full_rrp_fqs_march_22_2018.pdf

- Environmental Protection Agency (2018, May 22) Lead Test Kits. Retrieved from https://www.epa.gov/lead/lead-test-kits

- Environmental Protection Agency. (2022, November 17) Questions and Answers for Homeowners and Renters about Understanding Lead Inspections, Risk Assessments and Abatement. Retrieved from https://www.epa.gov/lead/questions-and-answers-homeowners-and-renters-about-understanding-lead-inspections-risk

- Environmental Protection Agency (2019, July 9) 40 CFR Part 745 Review of Dust-Lead Hazard Standards and the Definition of Lead-Based Paint, Final Rule. Retrieved from https://www.govinfo.gov/content/pkg/FR-2019-07-09/pdf/2019-14024.pdf

- Environmental Protection Agency (2021, January 7) 40 CFR Part 745 Review of Dust-Lead Post Abatement Clearance Levels, Final Rule. Retrieved from https://www.govinfo.gov/content/pkg/FR-2021-01-07/pdf/2020-28565.pdf

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!