Top Five Media Blasting Options

In the disaster recovery and restoration world, the media used for blasting is determinative to project outcome. Many historic buildings have delicate surfaces that often require a softer media. In the cases of disaster recovery, how to remove soot, coal, char and other unwanted items without damaging the structure has always been the center of discussions.

For the most part, there are five top media blasting options for recovery and restoration projects. In this article, we explain why these are the five superstar media to be used in disaster recovery and restoration. We discuss what each medium is most suitable for.

Sponge / Sponge Jet

Sponge jet is one of the most suitable blasting media for sensitive assets. Being a soft medium, sponges are friendly to surfaces. Therefore, according to spongejet.com, the sponge media is particularly suitable for “general corrosion projects, production-orientation facilities, unique substrates or challenging safety environments.” These projects include historic buildings affected by weather conditions. Such buildings suffered corrosion and wear, and thus require extra cautions when being worked upon.

Another reason why the sponge media is one of our top choices for recovery and restoration projects is that this specific media can reduce over 98% of the hazardous dust produced during blasting. The minimal dust creation is a significant advantage comparing to other traditional blasting media.

Dry Ice

Dry ice blasting is the new favorite solution for both media blasters and project managers. It is by far one of the most efficient and environmentally-friendly media available. As the solid form of carbon dioxide, dry ice particles turn into gas upon impact. Therefore, this method does not create any additional residues after blasting.

Being 100% dry, the dry ice medium is naturally one of the best solutions for mold remediation projects. Dry ice is often selected for projects in and around catastrophe restoration, manufacturing, industrial/food, and beverage facilities because these small particles can clean more in-depth into the surface texture without hurting the materials underneath. These small particles break down on impact and continue to force their way through cracks and crevices that other media particles are unable to reach.

The sponge is a dry, friendly and non-invasive medium. Photo courtesy of spongejet.com

Dry ice is Blast It Clean’s #1 selected medium. In November 2018, we applied mold remediation for a commercial facility. We blasted more than 56,000 square feet with dry ice, and the results were more than satisfactory. Another benefit of dry ice is that it’s highly efficient when multiple teams with different specialties are working at the same time. Sometimes blasting can interfere with other teams causing visibility and safety concerns. Since dry ice vaporizes upon impact, it minimizes disturbances on other teams such as the dust often created when using other media.

Baking Soda

Since the restoration of The Statue of Liberty in the mid to late 1980’s, baking soda abrasive blasting has continued to gain popularity in the blasting world. Now that traditional sandblasting has gradually exited the stage due to sand-caused silicosis among blasters, baking soda has become one of the most important methods used in restoration projects such as fire and historic restoration.

The baking soda medium is effective in removing post-fire residues, soot, and carbon from a variety of surfaces without causing severe secondary damages to the structure. It acts as a deodorizer as well in heavily affected fire and mold situations. When desired, baking soda cleaning is also an intensified method that exposes the integrity of the structure for engineering purposes. In these situations, blasters damage the surfaces purposefully so an engineer can tell if any parts of the structure suffered fire damages and need replacement.

Media blaster cleaning large machine parts with dry ice.

Walnut Shell

Being an organic abrasive medium, walnut shells are bio-degradable and completely toxin-free. Unlike sand which contains silica, walnut shells are non-hazardous both to the environment and to the blasting workers.

A quick example of where you would use walnut shell blasting would be on a surface such as wood and or a delicate metal to where you would not want to cause warping. Wood is naturally a soft surface compared to steel and other materials exposed to the blasting process. Other media produce a lot of heat when friction occurs causing delicate metals to warp. Walnut shell will avoid both of these situations.

Walnut is typically blasted at a lower PSI and produces much less dust compared to other mineral and slag materials. Thus, walnut shells reduce cleanup cost and secure the job process with better visibility.

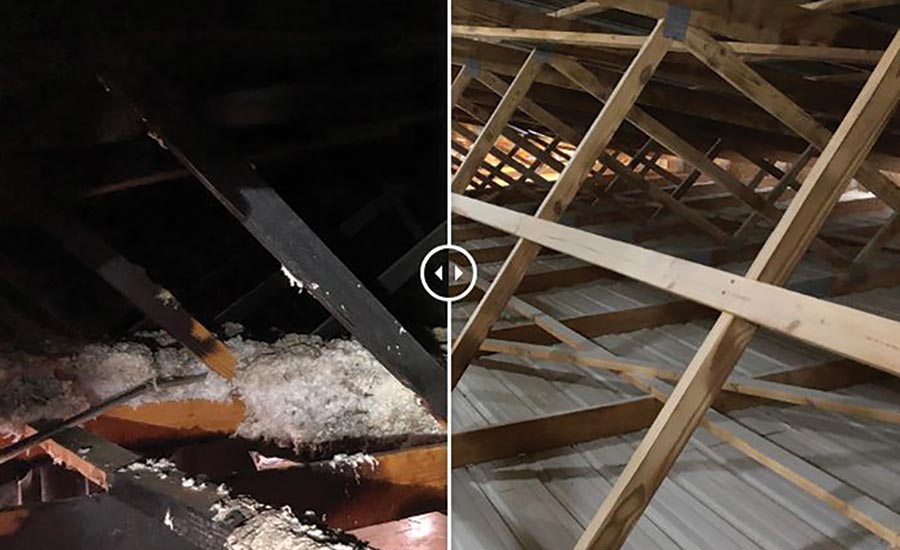

Left: ceiling structure before soda blasting Right: after soda blasting

Corn Cob

Corn cob is another organic abrasive medium. Therefore, it carries over most features walnut shells have. The corn cob medium is frequently used in log home restorations because it is one of the few materials that can restore the interiors and exteriors of a wood cabin to the original state.

Unlike using chemical cleaning or power-washing, corn cob is a dry medium which will avoid soaking or eating into the wood, therefore, the surfaces will be ready for a new layer of the selected coating application without extra drying time after blasting with corn cobs.

walnut shell medium

These are the top five blast media used in recovery and restoration projects. Dry media that cause less to zero hazardous dust. Softer media that avoid secondary damage to the surface are preferred.

However, some projects will require the use of a harder media to expose structural integrities so an engineer can evaluate the architecture as a whole after the blasting. Other blasting options for restoration projects include black beauty coal slag, crushed glass, glass beads and more. Eventually, it calls for experience and site assessment to decide which blasting method will be the best solution to complete the project.

Corn cob blasting a log cabin

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!