Cleaning Structures for Chemically Sensitized Individuals | Part 2: Source Removal

In the first part of this series, a number of core concepts were introduced including the:

- explanation of chemically sensitized individuals

- term “sensitizible”

- impact of gender, genetics, routes of exposure, and type of exposure

- importance of cleaning dust, since dust is the “carrier” for many chemicals

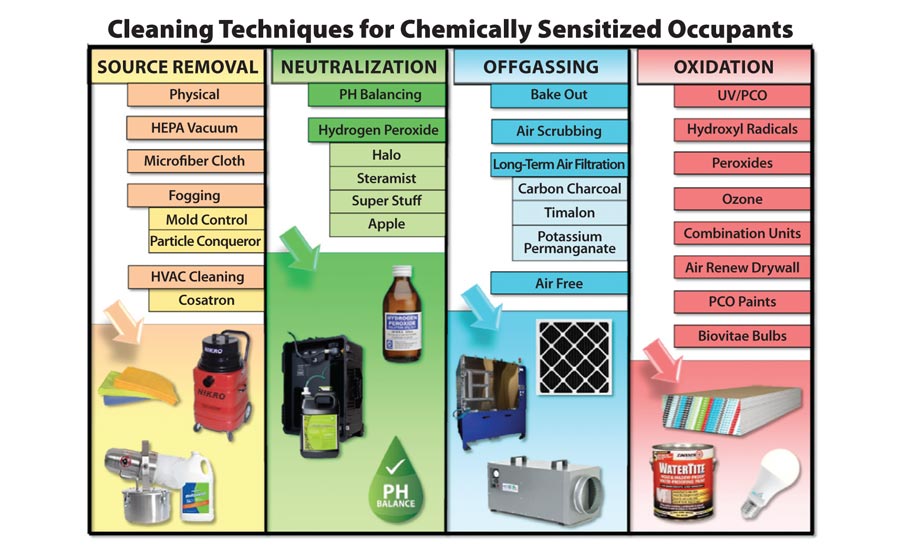

Now it is time to start discussing some specifics*. As we begin, it is important to remember that cleaning structures for chemically sensitized individuals involves the removal or control of chemical source material as well as the removal of chemical residues; including residue that has adhered to dust. Parts 3, 4, and 5 of this series will focus on removal or control of chemical sources through neutralization, off-gassing, and oxidation. In this segment we will focus on physical removal of the offending materials and cleaning techniques for the microscopic particles that also contribute to the problem.

Removal of Contaminant Sources

The physical removal part is pretty straightforward. If a mattress, pillow, couch, or other upholstered furniture has a foam component that is off-gassing, there may be no cheaper alternative than removing and replacing it with something that does not have an offensive component. The same may be true for particle board furniture, orient strand board (OSB) or medium density fiberboard (MDF) sheathing, or finished interior surfaces that will not cure out properly.

As radical as removal of building materials may seem, it is often much cheaper to address the problem head-on than try and “dance” around it with various treatment options and still end up facing removal when the other control techniques fail. Our organization recently assisted a homeowner who faced the daunting prospect of tearing out all the paneling in a recently remodeled basement recreation room. The remodeler used a beaded style MDF panel and the off-gassing created low levels of obnoxious odors that quickly started creating symptoms, even when she avoided entry to that basement room. The amount of installed materials and significant odor obvious from each piece argued strongly for quick removal. Instead, the owner chose to implement a number of potential curative techniques only to come to the conclusion the cost of deteriorating health was much more significant than replacement of an entire room of paneling.

Other situations also call for physical removal despite the complexity of such work. Many experts who deal with spray foam insulation confirm that poorly applied materials that do not cure properly during the initial installation often have to be removed. Presentations at industry conferences have graphically illustrated the problems in such situations by showing workers laboriously scraping foam from every nook and cranny of an interior wall cavity and even cutting the top of the entire house off when spray foam in the attic had to be removed.

Dust is the “carrier” for many chemicals.

Cleaning to Remove Microscopic Sources

Even if source removal is the primary approach to dealing with chemical sources in a building, detailed cleaning typically is also part of the process. While procedures for effectively cleaning small dust particles can seem extreme to individuals outside the cleaning and restoration industry, professionals have had to develop effective techniques in order to address a variety of environmental contaminants. Rather than reinvent the wheel, individuals involved in cleaning structures for chemically sensitized individuals should adapt the processes that have been proven effective for cleaning up asbestos fibers, lead dust particles, mold, and infectious agents. “Borrowing” products and techniques from other industries means that the process for effectively cleaning structures is constantly changing as contractors have an ever-growing toolbox full of products to rely on.

One of the most overlooked cleaning devices for the chemically sensitized occupants is the existing HVAC system. Low efficiency fiberglass filters (approximately 25% efficient for micron-sized particles) are utilized in many heating and cooling systems, but their main purpose is to keep dust and lint from building up on the heating or cooling coils. Such filters are not intended to improve air quality. In contrast, many moderate to high end HVAC units are now designed to work with medium and high-efficiency filters which can screen out up to 95% of micron-sized particles. Installing such filtration, along with a variable speed fan in the unit that can be set to run 24/7, will address large particle capture to keep higher background levels of small dust particles from building up in the structure over time.

Although it is just starting to penetrate into the residential market, some new technology will be a big boon to occupants who are trying to control chemicals and particles in their homes. Adding CosaTron air purification equipment to the HVAC system does not create any back pressure. It is a non-ionizing, non-ozone generating, electrical excitation technology that forces smaller particles to coalesce into larger ones so that the standard filters become more efficient. Interestingly, the CosaTron unit is installed on the HVAC system after the filter box rather than in front of it.

A Vacuum That Works

Another underappreciated cleaning device is an industry stalwart — the HEPA filtered vacuum. Although some sensitized individuals have been convinced that high-end, luxury vacuums are the only ones that will clean properly, this is far from the truth. There is no need to spend $1,200-$2,000 on a Miele, Electrolux, or Stimvac. In fact, a decade old report in the European Journal of Allergy and Clinical Immunology showed that many expensive upright vacuums did little to reduce the user’s exposure to pet allergens.

When advising our sensitized clients, we recommend regular cleaning with a canister-style HEPA filtered vacuum. We are quick to warn them that shop vacuums with HEPA filters are not effective. In fact, EPA tests to evaluate such vacuums shortly after they implemented their Lead Renovation Repair and Painting rules (RRP) showed that shop vacuums with HEPA filters can actually make the contamination situation worse because they are not properly sealed. That is why we direct our clients to reasonably priced industrial-style HEPA vacuums. Although we have experience with many of the leading brands in the industry such as Pullman/Holt and Nilfisk, we have found good value in regards to price and performance from Pro-Team and Nikro as well.

Many individuals in the cleaning and restoration industry are familiar with the “HEPA sandwich” cleaning process.

Supplementing the HEPA Vacuuming Process with Microfiber Cloths

While HEPA vacuuming is essential, it is only one step of the cleaning process. Many individuals in the cleaning and restoration industry are familiar with the “HEPA sandwich” cleaning process. This term describes a process where the HEPA vacuuming of surfaces is “sandwiched” around a damp cleaning wipe. Many thanks to my friend and colleague, Rachel Adams, for popularizing this process which has become such a mainstay in the industry.

One of the newer products available to supplement HEPA vacuuming is cleaning with microfiber cloths. While such cleaning cloths have been around for more than a decade, they typically have been utilized like enhanced shop towels. Because of the initial expense of the microfiber cloths, it led to their being used repeatedly with washing in between each use. Unfortunately, microfiber towels are not shop towels. To maintain their performance characteristics, they have to be laundered in a very precise way using specific cleaners. The wrong chemicals, water temperature, wash/rinse sequence, or drying temperature can ruin the microfiber towels so that they just smear small particles around instead of removing them up. Worse yet, in situations where microfiber cloths are used to assist with the cleaning of contaminants, washed cloths may actually contribute to cross-contamination.

Due to some of these difficulties in properly maintaining microfiber cloths, which are just now starting to be widely shared in the restoration industry, there is a big move toward single-use microfiber cleaning products. The recognized leader in this industry is Contec with the Primera products that they developed for infection control purposes in the healthcare industry. These products have migrated over to the remediation and restoration industries and are especially good for mold remediation, asbestos abatement, and lead dust cleanup; in addition to their original intended use for infection control. One of the reasons that many people are substituting wiping with a dry microfiber cloth as the last step of the HEPA sandwich process (does that make it a HEPA pizza?) is that microfiber cloths have their own electrical charge which helps break the “static electric cling” holding spores and other small particulates to sheet plastic

Still, just having microfiber cloths in your “toolbox” does not mean that they will be effective. Everyone on the crew needs to know how to use them. Training and the proper accessories make all the difference in regards to how effective microfiber cloths are under real world conditions. Studies from the healthcare arena have shown that using microfiber cloths on a backing pad dramatically increases their effectiveness of picking up microscopic contaminants.

The best backing pads have a swivel heads because microfiber cloths should be pushed across the surface to be cleaned so that the cloth always moves in one direction. A back-and-forth cleaning motion allows some of the particulate that has been picked up by the cloth to be dislodged. Having the cloth on a swivel head means that the cleaning can be done in an S pattern that always keeps the leading edge of the microfiber cloth at the front of the cleaning motion. Obviously, there should be a bit of an overlap on each of the strokes to make sure that none of the surface area is missed during the cleaning.

The last, but perhaps most important, part of the training related to the use of microfiber cloths is to ensure that the disposable cloths are changed frequently. Even if they do not look very dirty, cloths used for final cleaning should be disposed after wiping small sections of walls or floors. For initial cleaning after HEPA vacuuming, we instruct workers to clean only 50 to 100 square feet of wall, floor, or other surfaces before changing cloths. For final cleaning after passing the visual inspection, we recommend changing the towel every 200 to 400 square feet.

Cleaning the Air

Regardless of which pieces of equipment and work procedures are used, detailed cleaning of a structure will result in the addition of airborne particles. Rather than letting those particles settle, the cleaning process should also take into account cleaning of the air. This is typically done by setting up HEPA filtered negative air machines in the “air scrubbing” mode so the room air has an opportunity to pass through the filters multiple times.

Regardless of which pieces of equipment and work procedures are used, detailed cleaning of a structure will result in the addition of airborne particles.

When using a negative air machine as an air scrubber, it is generally best to control the flow of exhaust air so it does not come out under high pressure. This is accomplished very easily by attaching a “tail” to the exhaust port on the machine made of plastic sheeting in a tube/hose shape. Generally, 15 to 30 feet of tubing is attached with the exhaust end of the plastic sealed. When the machine is turned on, the hose will blow up like a balloon and then semi-circle cuts can be easily made in the length of the plastic on three sides. This arrangement will allow the air to diffuse gently in a variety of directions throughout the room. Because the small particles that are being cleaned are aerodynamically active, attaching the diffuser tail is important to keep particle levels from stratifying in the structure; a situation which allows the heavier particles to be captured and the lighter ones to recirculate.

If the CosaTron unit mentioned previously is not in place, other techniques may be necessary to get small particles in the air to amalgamate into larger groups so they can more easily be directed toward the air scrubber and removed. The most common way to accomplish this is through “air washing”. This process uses an airless sprayer or ultralow volume (ULV) fogger to eject small droplets of a liquid into the air which helps to bind particles together. Thermal foggers are typically not used in such situations due to the type of products that are typically used for air washing are not compatible with the heat.

Both simple and commercial products can be used for air washing. Regular water is a common choice but there is some evidence that small particles that are bound by water tend to separate fairly quickly due to evaporation. Because of this limiting factor, a number of commercial products have come into the marketplace specifically designed for air washing. Mold Control by Concrobium was one of the first products designed for a fogging application in the mold remediation industry. As a salt solution, Mold Control is generally tolerated very well by chemically sensitized occupants, but it typically leaves a residue on horizontal surfaces that have to be wiped off after the fogging. Particulate Conqueror from Bad Axe Restoration Products is based on a different chemistry that incorporates multiple surfactants to get the water to break down in small droplets with different electrical charges, thereby forcing small particles to come together and stay together. Depending on the circumstances, some wiping may be necessary after the fogging of any product.

Of course, with chemically sensitized individuals, the atomization of any chemical into the air of the structure, including tap water which can include any number of minerals and chemical compounds, should be considered carefully. Make sure that the benefits (increased particle mass which improves filter capture efficiency) are worth the risk (adding another substance to the structure with a sensitized occupant).

Source Removal and Cleaning Are Only Part of the Puzzle

Addressing the needs of chemically sensitized building occupants takes significant effort. Source removal involves more than ridding structure of the offending material. Cleaning of both surfaces and the air are critical aspects of the work. If that does not resolve the issue, the chemical residue may have to be neutralized in place — the subject of the next article in this series.

*As noted in the initial part of this series specific products and brand names are mentioned to assist the reader in making potential purchase decisions. Neither Wonder Makers nor the author have any direct sales relationship, referral fee arrangement, or other financial connection to any of the organizations to encourage the mention of their products. Please see the first part of this series for additional details regarding this disclaimer.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!