The Truth About HEPA Filters

Understanding the science behind HEPA Filters and the myths that marketing wants you to believe

Photo courtesy of ARTI

In restoration and remediation, few pieces of equipment are more relied upon, and misunderstood, than the HEPA filter. The term is printed on air scrubbers, vacuums and negative air machines across every jobsite, but ask many professionals in our industry and you’ll find that few can actually explain what it means. Even fewer understand the science behind how these filters work, or their limitations.

A common misconception in the industry is that HEPA filters only capture particles “down to 0.3 microns,” as if anything smaller escapes filtration. In reality, 0.3 microns represents the point of lowest efficiency, not the smallest particle a HEPA filter can capture. Due to the physics of how particles behave at different sizes, HEPA filters are actually more efficient at capturing both larger and smaller particles than this point. Unfortunately, this nuance is often exploited by marketers who present selectively framed data to make one filter appear superior to another. The reality is, our understanding of HEPA filters has been shaped more by marketing than by physics.

This article will break down the core mechanisms that make HEPA filters effective, identify where their performance peaks, and where it falters, and give industry professionals the technical clarity they need to properly explain HEPA function and to see through the misleading advertising that plagues American capitalism.

Mechanisms of Capture

HEPA filters trap particles using three primary physical mechanisms: diffusion, interception and inertial impaction. Each operates most effectively within a specific particle size range, and together, they allow HEPA filters to capture an exceptionally wide spectrum of contaminants. These mechanisms do not rely on a simple sieve-like structure; rather, they leverage particle motion and fiber interaction to achieve high filtration efficiency.

Diffusion (< 0.1 µm):

For ultrafine particles — such as viruses or submicron combustion aerosols — random molecular collisions cause the particles to move erratically in the airstream, a behavior known as Brownian motion. This erratic movement increases the chance that a particle will come into contact with a filter fiber and be captured. The smaller the particle, the more strongly diffusion dominates, which is why HEPA filters can effectively capture particles well below 0.3 µm.

Interception (0.1 – 1.0 µm):

Particles in this size range tend to follow the airstream as it bends around the filter fibers. If the particle’s trajectory brings it close enough to a fiber it can adhere to the fiber surface through weak molecular attraction.

Inertial Impaction (> 0.5 – 1.0 µm):

Larger particles have enough mass that they cannot follow the curvature of the airstream around the fibers. Instead, they continue on a straight path to directly impact and adhere directly on a fiber. The greater the particle's size and velocity, the more likely impaction becomes the dominant mechanism. This captures particles like pollen, mold spores and visible dust.

Because these mechanisms overlap, HEPA filters maintain high efficiency across the entire respirable range. The area around 0.3 µm represents a dip in overall performance because it's the size range where none of the three mechanisms are strongly dominant, which is exactly why HEPA filters are tested at this point.

The MPPS

The Most Penetrating Particle Size (MPPS) is the size range at which a HEPA filter is least efficient, typically around 0.3 microns, although depending on the filter’s construction and media density, it can vary down to 0.1 microns. This is the point where the three primary capture mechanisms - diffusion, interception and impaction - are all at their weakest.

Particles at the MPPS are too small for inertial impaction to be effective and too large for Brownian motion to cause strong diffusion. As a result, they have the greatest likelihood of bypassing the filter media. This is precisely why manufacturers test HEPA filters at this particle size and why it is the golden standard. If the filter performs well at its weakest point, it will perform even better across the rest of the size spectrum.

A persistent myth in the restoration industry is that HEPA filters only capture particles “down to 0.3 microns,” as stated in the introduction, when in fact this is the size they capture least efficiently, not the smallest they can filter. Particles smaller than the MPPS are generally captured more effectively through diffusion.

The HEPA Efficiency Standard

By the U.S. Department of Energy’s (DOE) definition, a HEPA filter must capture 99.97% of particles at 0.3 microns. This standard is often misrepresented. Phrases like “filters down to 0.3 microns” are misleading, as they imply smaller particles are not captured when, in fact, they usually are with even greater efficiency.

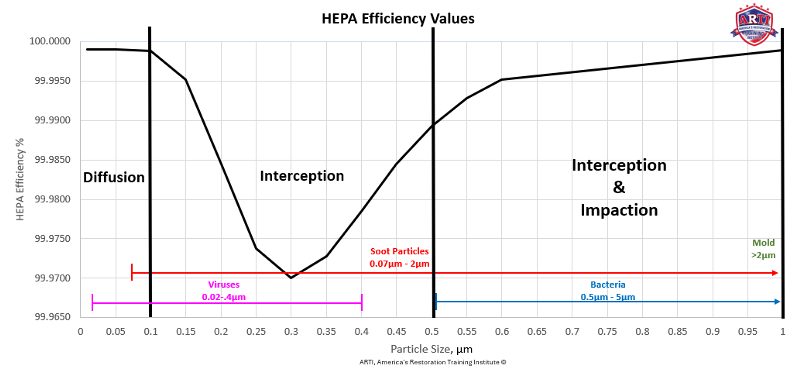

The chart shown below illustrates this concept clearly. The black curve represents the efficiency of a standard HEPA filter across a range of particle sizes. The lowest point of the curve sits at approximately 0.3 microns, representing the MPPS. To the left of this point, efficiency improves due to diffusion, while to the right, interception and impaction take over. This forms the characteristic "bell-shaped" dip that defines HEPA performance.

Also plotted on the chart are the approximate particle size ranges for various contaminants:

- Viruses (pink) typically range from 0.02–0.4 µm, which falls within the diffusion dominant range, but also in the less efficient range of interception within the MPPS zone. Larger virus-laden aerosol vehicles (i.e. dust), often found in real-world environments, are more likely to be captured the larger the aerosol particles are.

- Soot particles (red) typically span 0.07–2µm, crossing through the MPPS zone.

- Bacteria (blue) tend to be 0.5–5 µm, well within the interception and impaction range.

- Mold spores (not within shown range, but typically 2–20 µm) fall entirely outside the MPPS zone, and are easily captured by HEPA filters via impaction.

This visual reinforces our main takeaway: 0.3 microns is not a lower boundary; it is the weakest point. Any filter that meets the HEPA standard will outperform its rated efficiency on particles smaller and larger than this benchmark.

Graphic courtesy of ARTI, America's Restoration Training Institute

Air Velocity and Particle Behavior

Particles smaller than 0.1 microns behave very differently than their larger counterparts. Instead of moving in straight paths through the air, they drift erratically due to Brownian motion, a phenomenon caused by constant collisions with surrounding air molecules. The smaller the particle, the more it is influenced by these random impacts. This chaotic motion dramatically increases the chances that a particle will contact and adhere to a filter fiber.

It’s a reasonable assumption to think that increasing airflow velocity might enhance a filter’s ability to capture smaller particles. After all, when you blow on visible dust in a beam of sunlight, you observe an increase in erratic motion. However, those visible particles are often tens of microns in size and behave according to different physical principles than ultrafine particles. True Brownian motion is driven by thermal collisions with surrounding air molecules. The random, chaotic movement you see in sunlight is due more to turbulence or air current eddies, not molecular-scale kinetic activity.

In the case of HEPA filtration, increasing airflow actually reduces the time ultrafine particles spend within the filter media. This decrease in dwell time or increase in air velocity reduces the chance that these particles will contact and be captured by fibers via diffusion. Higher flow rates can enhance impaction-based capture for larger particles, but they can compromise performance in the submicron range, particularly near the MPPS. That’s why HEPA filters are tested and rated at specific flow rates, typically 85 liters per minute (L/min) for small test filters under DOE protocols, and why AFDs should be sized appropriately for the space, rather than simply turned up to maximum CFM if your goal is to capture these ultrafine particles.

The Lower Limit

HEPA filters are highly effective down to about 0.003 microns, where below this point filter efficiency drops rapidly because this particle size is entering the molecular range, which is too small to be captured by mechanical filtration. Gas molecules, odors and volatile organic compounds (VOCs) typically fall below 1 nanometer (0.001 µm), well beyond the reach of HEPA.

At this size, particles no longer behave like solids; they act more like free-floating gases, passing straight through filter fibers. This is why HEPA filters can’t remove odors or chemical fumes. For true gas-phase filtration, activated carbon or other adsorbents are required. Understanding this limitation helps ensure the right filtration tools are used.

Misleading Advertising

Not everything labeled “HEPA” performs like a true HEPA system. Many vacuums, air scrubbers and AFDs are marketed as “HEPA” simply because they contain a HEPA-rated filter. To be a true HEPA unit, all air must be forced through the filter without bypass, which requires many internal parts to be completely sealed. Leaks in the housing, gaskets, or filter edges can allow unfiltered air to escape, resulting in what’s called breakthrough, air moving around the filter media. This means that the machine is not delivering HEPA-level performance, defeating the purpose entirely.

Another common tactic is selectively advertising filtration efficiency at particle sizes where HEPA filters naturally perform well at. For example, a product might claim “99.99% efficiency at 0.1 microns” as if it outperforms other filters, but this is expected behavior for any properly functioning HEPA filter due to how diffusion works. What matters most is performance at the MPPS, not cherry-picked data that looks impressive on paper. This is of course, excluding filter structure that varies below the typical MPPS.

Professionals should look beyond marketing terms like “HEPA vacuum” or “HEPA filtered” and demand test data or certifications that confirm performance at the standard 99.97% efficiency at 0.3 microns and ensure the equipment is built to maintain that performance in real-world use. A stipulation I have come to require is for the efficiency rating of 99.97% at 0.3µm to be achieved at the unit exhaust, that way tools such as a particle counter can be used to verify that the HEPA unit is performing correctly.

Conclusion

The term “HEPA” is everywhere in our industry but understanding what it truly means and doesn’t mean, is critical. These filters are powerful tools for capturing airborne particles that we use on just about every job, but their performance depends on more than just installing the right filter media or picking the shiniest piece of equipment. Factors like particle size behavior, air velocity and equipment design all influence actual effectiveness on the jobsite.

Too often, marketing oversimplifies or distorts how HEPA filters actually work. Professionals should be cautious of exaggerated claims and vague labels. I recommend that efficiency ratings be verified at the point of exhaust, using standard particle sizes and recognized test protocols. This is the only way to be certain that the system performs as intended while monitoring it in the field.

In an environment where air quality control directly impacts health, liability and trust, we owe it to ourselves and our clients to go beyond the label. Understanding the science behind HEPA filtration allows us to select the right equipment, verify its performance, and do our jobs with greater precision and confidence.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!