A Moisture Meter Primer: Which One Do I Use?

Water damage restoration work requires contractors to quickly assess and remediate to prevent further structural damage, mold growth, and other moisture-related issues. Correct assessment of the moisture conditions inside a damaged structure requires the right tools for testing the ambient conditions and moisture content of various building materials such as drywall, wood, insulation, and flooring.

Proper use of moisture meters in a water damage or mold remediation claim is critical to your success as a restorer — and to your reputation. The health and safety of the occupants of both commercial and residential buildings is dependent on you.

With a quality moisture meter and thermo-hygrometer you can:

- Quickly define the areas in a structure that are affected

- Identify what kind of drying equipment is best for the job

- Monitor overall drying progress

- Verify the structure is dry before removing equipment

Pin and pin-less moisture meters are the two meter types used throughout the industry. Knowing how they work, what each can and cannot do, and what information they provide will help ensure you are making the most out of whichever type and brand of meter you use.

Which Meter Should I Use?

According to many industry pros, most use both. It is hard to beat the convenience of going into a building to quickly survey the damage with a pin-less meter and then to follow up with more complete testing of problem moisture areas with a pin meter and special application electrodes.

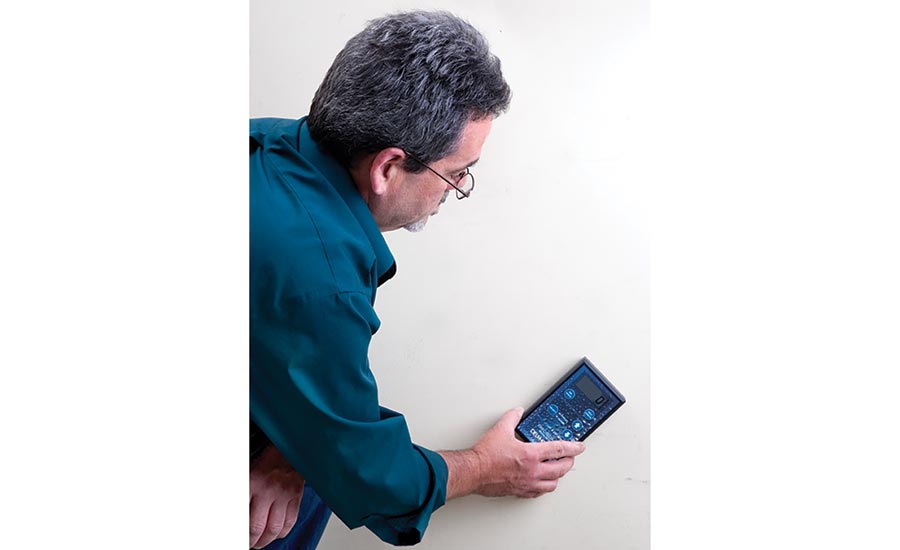

Pin-less meters use RF (capacitance) technology to detect the presence of moisture. The meter’s sensor pad must be in full contact with the material being tested. The meter transmits and receives a low frequency RF signal and outputs the difference between the two, as an indication of the moisture present. This is especially useful for meters that provide relative moisture levels (dry to wet) readings on building materials. Some meters use more sophisticated RF circuits and so are able to provide quantitative (%MC) readings on wood.

The convenience and efficiency of a pin-less meter is appealing, however there are some important limitations to consider:

- Material surface should be smooth to ensure sensor contact.

- Surface moisture generally skews the meter reading. This varies among the meters available, but one should understand the impact of surface moisture and how it affects the behavior of the specific meter.

- Penetration depth is limited to about ½ to ¾ inch with most meters.

- Hidden objects like electrical boxes, wires, and metal studs can impact the readings.

- Hard-to-reach areas are just that — hard to reach.

Pin meters are based on conductance. There is a well-defined, direct relationship between the moisture content of wood and its electrical resistance. This can be extended to drywall as well. Repeatable, relative readings can be obtained on virtually any hygroscopic building material. Two electrode pins are driven into the material, and the meter measures the resistance between them, as influenced by moisture present. The meter displays the %MC if on a calibrated scale, or a relative number that may be used for comparative, wet/dry readings.

The major limitation of a pin meter is that it cannot cover large areas quickly. Some have concern about leaving holes in the material. This is a non-issue when you consider the damage already present in a water-damaged environment and the damage that may develop if moisture were left undetected.

Pin meters offer built-in corrections for material temperature, species, and type of electrode. These are most important when measuring wood MC. The technician can implement or disregard, depending on the application and accuracy required.

Special Application Electrodes

A great feature of pin meters is the ability to use external electrodes that enhance the meter’s functionality for a more complete moisture evaluation process.

Special application probes include tools that are simply an extension of the integral electrode pins on top of the case, used for less accessible areas. Deep-wall electrodes with 3-inch insulated pins (except for the tips) come in handy when checking for the presence of moisture in insulation behind drywall. They are also effective for investigating EIFS or synthetic stucco-clad structure issues, and roofing materials.

One of the most versatile and popular electrodes in restoration is the slide hammer type with insulated pins (max penetration 1in+). The pins make contact with the material at their non-insulated tips to provide more accurate readings at specific points of penetration. This feature allows you to penetrate through flooring and into the subfloor. It is also useful for plywood and other engineered materials.

Another versatile, must-have electrode that can help save time and unnecessary demolition is the blade type. It has two 5-inch-long partially insulated blades that are bent to a 35° angle. This handy tool is ideal for checking behind trim, baseboards, and under sill plates. This type of electrode is also great for checking moisture in books and documents.

What Does the Reading Mean?

Most moisture meters, both pin and pin-less, implement material scales that give the water damage technician the flexibility to “measure” different building materials. Most meters feature a “wood” scale and some a drywall scale for a direct reading of %MC. Almost all meters in use today utilize at least one “relative” scale for comparative readings on non-wood materials. These also can be called reference or comparative scales. Some use the term “WME” because the reading is an indication of what the material would attain if in close contact and equilibrium with wood, expressed as a percent moisture content of wood. These arbitrary scales vary in range from 0-100, 0-200, 0-300, and 0-1000.

Since pin meter and pin-less meter technologies respond differently to the presence of moisture, it is difficult to make direct comparisons between scales and readings, and especially so among the scales from manufacturer to manufacturer. It is important to understand the basis of the calibration of each scale of the meter of your choice. Get comfortable with how your meter behaves on specific materials and under varying conditions.

Moisture meters are proven to aid in the efficiency in a drying operation. They are essential tools in the industry. Some are very simple point-and-shoot-type products while others are feature-rich, combination pin/pin-less/thermo-hygrometer devices. Regardless of which meter type, model, or brand you choose, keep it calibrated and in good working order at all times, and follow the manufacturer instructions.

The old adage that “you get what you pay for” certainly applies to the moisture meters available today. A high-quality and robust moisture meter, built for the restoration environment and supported by a reputable and experienced manufacturer, is one of the best investments a restoration company can make.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!