Exposing Restoration Equipment Misconceptions

Uncovering the myths and truths about restoration equipment to help you make informed decisions.

All photos courtesy of Elan Pasmanick

Our industry depends on science to bring us the best tools to do our jobs. Unfortunately, some claims are more like science fiction. It is often oversimplified, misunderstood or even manipulated to sell us a story. When restoration manufacturers, schools and associations spread ideas that affect the way we invest hard earned money in our equipment; we must make sure those ideas are based on facts.

Usually, you’ll find me working quietly in the corner of someone’s warehouse, but as one who has serviced thousands of pieces of equipment with my own hands, spoken to hundreds restoration business owners, managers and employees and as one who works directly with most of the largest manufacturers and consulted with some of them about their build quality, I’d like to share some of my insights that I think will increase your knowledge, help you understand your equipment better and help guide you in investing in new equipment.

LGRs are NOT the best

LGR dehumidifiers are often regarded by many as the best refrigerant dehumidifiers. As an individual with individual needs I have a problem with broadly defining something as the ‘best’. Instead, I prefer talking about the nuances of the pros and cons. Yes, cons do exist.

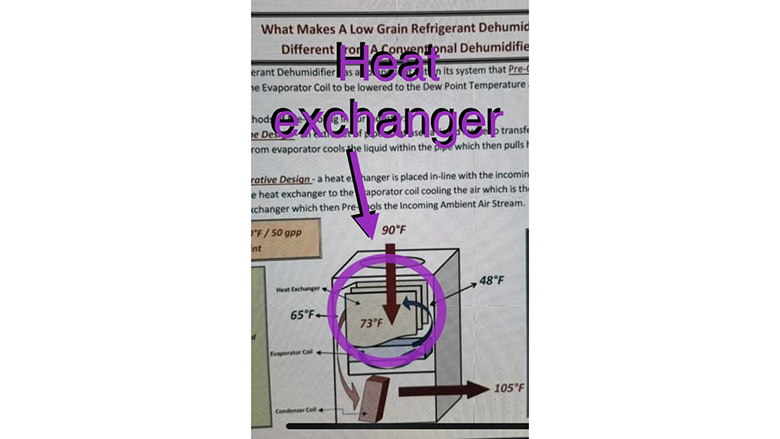

Here are the two major problems I have with the LGRs. First, many dehumidifiers are labeled LGR even though they don’t have the defining component, the pre-cooling heat exchanger. Second, the heat exchanger, as applied in the industry, increases the size of the dehumidifier to about twice the size it would otherwise be. This significantly reduces the amount of dehumidifiers that can fit in a van or a truck.

According to the science, to extract water from the air, the air’s temperature must be lower than the dew point, the temperature in which the air is saturated with water vapor. Below it the moisture condenses.

The dew point depends on the humidity level and the air pressure. The lower the humidity levels are, the lower the dew point gets. When using a dehumidifier, it lowers the humidity levels over time. The evaporator coil cools to lower the temperature of the air going through it below the dew point, but it is increasingly lowering. In addition, the air in the containment is getting warmer and in return warms the evaporator as warmer air goes through it. At this point to combat the low humidity levels and the high ambient temperatures a strong compressor is required for the dehumidifier to still be effective. This means more energy, or higher amperage, is needed.

Here is where the heat exchanger comes into the picture. It slightly cools the air before it reaches the evaporator, allowing the evaporator to reach a lower temperature when it is not heated by hot air and can more easily get the air to reach below the dew point, reducing the need of a strong compressor. But at what cost? Does doubling the size of a dehumidifier justify the energy savings? How much energy exactly is saved?

These questions aren’t answered by manufacturers, but aren’t even relevant when considering my first point, that most models of dehumidifiers that are labeled ‘LGR’ DON’T EVEN HAVE A HEAT EXCHANGER. Even models made by the largest, most respectable brands are regular dehumidifiers with a misleading label. This label became a marketing ploy.

I can’t publicly say which models are true LGRs and which are not, but I can tell you how to differentiate them. The heat exchanger is visible in true LGRs’ air intake. If you look inside, you’ll see sheets of black plastic that are glued together. Regular dehumidifiers have metallic coil fins in the air intake, that’s the evaporator.

The misconception “LGRs are the best” needs to disappear, it needs to become “LGRs are better for specific needs”, and if they do have a heat exchanger the savings of energy should be transparent for us to be able to make the right decisions for ourselves before buying new equipment.

Dehumidifiers are not made for heating

Many people think that dehumidifiers have a heating element and often where it is when I demonstrate a breakdown of a dehumidifier or when I’m repairing their equipment. The condenser by itself is a heating element, but it only dumps out the same heat energy that is absorbed by the evaporator. In a dehumidifier, air flows through both, so ideally, the air intake should be the same temperature as the exhaust. The extra heat comes from system inefficiencies, like refrigerant gas in the tubes and of the motor in the compressor.

This is a happy coincidence for the restoration industry, but a problem in others, like in the greenhouse industry, where air conditioners are also used to lower the air temperature.

Breakers and GFCIs are very different

This is a subject that confuses a lot of people but is actually very simple. A breaker is a component that stops the flow of electricity (opens the circuit) when the current is over the one rated by the manufacturer. In restoration equipment this is to protect the wires or other components from overheating.

A GFCI is a component that opens the circuit when there is a “leak” of electricity from a circuit. For example, when someone touches a live wire, or if the circuit gets wet. This is to protect from electrocution.

In a daisy chain of air movers, if too many air movers on the same line, a breaker will pop. If an air mover has a broken outlet and someone sticks a finger in it, the GFCI will pop. Breakers and GFCIs are not interchangeable, each has a very specific duty. Knowing these differences can help to find the problem, when one of these components pop.

Maintenance doesn’t have to be so often

For dehumidifiers performing maintenance regularly can ensure that they don’t malfunction on a job site and can also extend their life. Maintenance includes checking the filter, cleaning the coils, cleaning the condensate collection tray and the pump input line, cleaning the pump, checking the purge tube for kinks and leaks and checking its connectors, especially the O ring. If the O ring is cracked or damaged, replace it with a 7/16” OD 5/16” ID O ring that you can find in any hardware store.

Information about most of this is available on every manual and manufacturer’s website. The frequency is debatable, with some manufacturers saying one a year, some say once in six months and some even once a month. However, they don’t speak about the measures you should take that will allow you to significantly extend the time between maintenances and significantly extend the life of your dehumidifiers. Those measures are all about keeping them clean.

Here are four ways for keeping your dehumidifiers clean:

- Always use clean filters. When the filters are dirty, air can’t flow through them and the air will find a different way in, carrying dirt and dust with it.

- Never leave equipment in a containment during the demolition phase. Before introducing the dehumidifiers, or any type of equipment for that matter, wait for all the dust to settle and cleaned.

- When loading the garbage bags into your van or truck, don’t put them directly on your equipment. Splinters, pieces of drywall, screws and nails always find their way into the equipment, causing pump malfunctions and clogs in waterways. If there is no room or for some reason there is no other option, cover the equipment with a plastic sheet before laying the garbage bags on top.

- If you did the above and your coils are still dirty, never use air pressure to clean them. This just pushes dirt and dust into the dehumidifier. Instead, use a vacuum and a toothbrush in the direction of the fins to gently remove dirt.

If you found this information useful, spread it in your company. If you have influence among the manufacturers, distributors or restoration schools, please reach out to them, show them this article and ask them to update their pitches and/or curriculum. We must work together to improve the quality of our work. We must ask questions when what we think we know doesn’t make sense. Sometimes we can even learn from the guy who works quietly in the corner of your warehouse, if we just keep an open mind.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!