PPE Should be Your Last Line of Defense

There is no room for error in restoration when dealing with employee and occupant safety. The restorer must consider other options before resorting to personal protective equipment (PPE). Restorers are exposed to too many situations where hazardous materials, pathogens, and other toxic substances are present, even on the most “routine” restoration jobs. If your business is not protecting your workers, you are probably not protecting your customers either.

Most of us understand that grabbing personal protective equipment (PPE) out of the truck is the last resort and a proper site safety assessment should be completed first. But there are many restorers who approach this in a wildly different manner in regards to their day to day job functions.

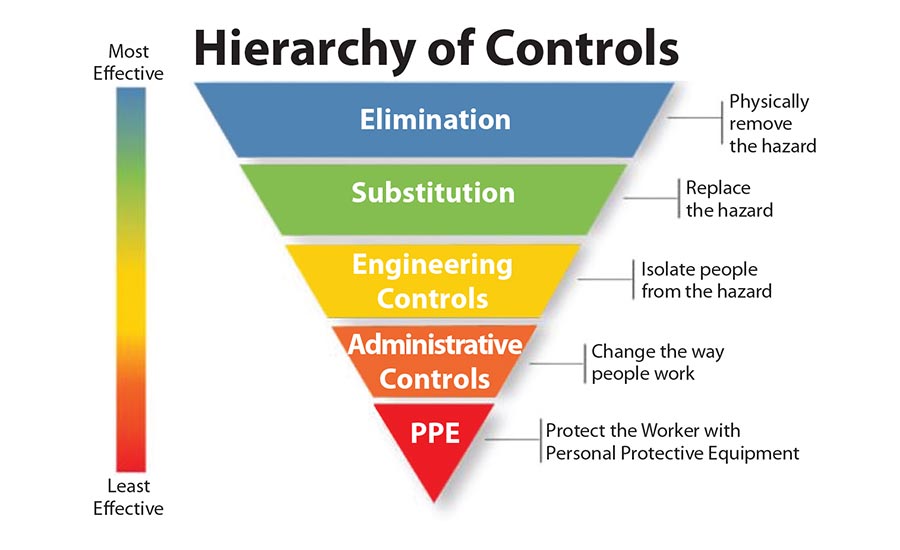

Before we talk personal protective equipment, let’s talk about The National Institute of Occupational Safety and Health (NOISH) Hierarchy of Controls.

Every job, every day, and every change in jobsite conditions requires the restorer to perform and update a jobsite risk assessment or job hazard assessment. This is the first step to identify the risks that are on the site and executing a control plan for the site.

Job Hazard Assessment/Job Risk Assessment

A Job Hazard Assessment is used to evaluate the risks that workers are exposed to and attempt to eliminate the hazard. When the elimination of a hazard is not possible, using personal protective equipment is necessary.

A restorer can easily use the Hierarchy of Controls to eliminate the risk, substitute the hazard, apply engineering controls to isolate people from the hazard, change the way people work using administrative controls, or finally protect the worker with personal protection equipment.

Elimination and/or Substitution

While these are the most effective methods of handling a risk, they can sometimes be very difficult to apply in the real world, especially in a restoration environment. A restorer can simply ask if there is a safer way to perform the task at hand or reduce the hazard of the job. Can you use fewer harsh chemicals or can you use different tools that reduce the risks to the worker? Simple risks may have a simple solution. For example, a trip hazard due to electrical cords being placed across a hallway floor may be eliminated by hanging the cords along the ceiling, eliminating a trip hazard.

Engineering controls

If you cannot eliminate or find a better way to do the work, can you apply a process or piece of equipment to reduce the risk? These actions are considered more effective and are preferred to administrative controls and PPE. Engineering controls are effective at isolating people from the risk. In a residential water damage job, we commonly use containment barriers to prevent homeowners from easily accessing the jobsite. It is most effective to put engineering controls at the source of the risk. In the case of dust containment, your engineering control could be a HEPA vacuum at the source of the dust, as opposed to an air scrubber in the middle of the room. However, the air scrubber is a great engineering control to assist in capturing dust and debris that is airborne as a result of the drying processes.

Administrative Controls

How are you going to work? This may include changing your schedule to work during a time with fewer interactions with occupants. You may implement safe driving practices, like no talking on a cell phone while operating a motor vehicle. Training staff on equipment or processes is another way to reduce your risk. This makes sense if you are working in a commercial space or a retail outlet where customers are coming into the work area. It may be safer to work after hours when you are free of employees and customers in your workspace.

Personal Protective Equipment

The final line of protection is the use of personal protective equipment. This protection is used when the risk cannot be reduced enough to provide a safe working environment for the worker. Restoration companies use the full range of PPE offered such as fall protection devices, hazardous material suits and full respiratory protection to confined space gear.

Remember that OSHA requires you to complete a PPE Hazard Assessment. We will discuss this in part 2.

Safety Drives Profits

Safety is a double-edged sword that can bring your company to its knees if you don’t respect it, or it can increase your average margin when you do. If a contractor fails to protect their staff and their customers, they increase their risk and increase the liability that the business will incur losses and fines as a result. However, there is a dramatic swing that happens when safety is incorporated in the jobsite. The company that follows regulations and follows the laws surrounding safety, can charge for those processes to be followed and dramatically reduce the potential for fines and work stoppages. This increases profitability while also reducing the risk to your business and your staff. A company’s safety strategy is the single most effective part of protecting your bottom line and your reputation of protecting their workers and clients.

Become a Power Restorer

In order to move up in the game from residential small losses to medium sized commercial claims and then into the medical, large industrial and large commercial jobs you need to be safety minded. It is your job to look professional and keep control of the worksite. You can’t be standing in the firing line with lame excuses as to why you didn’t follow the Hierarchy of Controls or made the choice to not abide by OSHA when it is your job as a contractor to follow the laws and your workers.

If you haven’t taken the IICRC Health and Safety Technician course, I recommend that you sign-up for one today. This should be one of the first courses you take, because every decision about your use of products and processes you deploy should be safe for the workers and occupants of the project.

Remember - Safety First!

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!