What You Need to Know About Hydroxyl Generators

Credit: Xiaoxing Zhao/Creatas Video via Getty Images

The main benefit of using a true hydroxyl generator is that they are safe to use in occupied areas for deodorization purposes. Insurance companies do not have to cover a homeowner’s hotels or meals. Business owners do not have to shut down and lose precious business.

If people and animals can be removed from the treatment area, ozone will always do the job faster. And the general rule of thumb is if a strong ozone generator would take one day to do a job, a true hydroxyl generator will take three to five days to do the same job. But insurance companies don’t seem to have a problem paying for the extra time it takes a hydroxyl generator to do the job because they are saving on hotel and food costs and their customers are much happier staying in their own homes and businesses. In saying this, hydroxyl generators are commonly one of the first pieces of equipment installed on the job and can be run the entire length of the job. These machines are already in Xactimate and bring in some $200 per day on a rental. With the price of the hydroxyl generators on the market, there would be a 100% return on investment within the first week of use.

Related Reading

These generators have been successfully tested on fires and other restoration and bio jobs, including protein fires, floods, dead body situations, skunk odors, pet urine odors, musty odors and many types of VOC odors. Many restoration contractors have converted existing deodorizing chambers or added their own hydroxyl rooms with great success. You can run a hydroxyl room 24 hours a day and enter the room at any time with no threat to your health. True hydroxyl generators also will not bleach wet fabrics so they can be run on damp carpet without fear of lightening the color.

However, it’s important to note that hydroxyl generators are not intended for use on mold remediation jobs where there is a large infestation on surfaces or behind walls. The established protocols should always be followed in these instances. But generators with good filtration are excellent for airborne microbial remediation where bacteria or fungi have become aerosolized.

Here’s a look at more information and considerations for this type of deodorization.

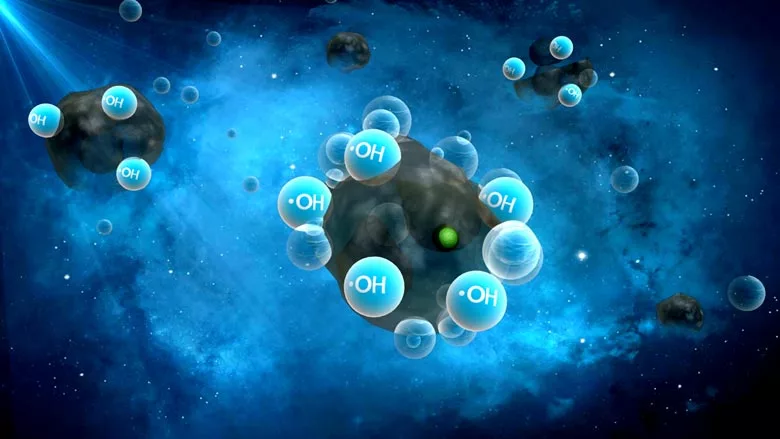

What Is A Hydroxyl Radical?

The hydroxyl radical, •OH, is the neutral form of the hydroxide ion (OH–). Hydroxyl radicals are diatomic molecules that are highly reactive and very short-lived with an average half-life of less than two seconds. The hydroxyl radical which was first discovered by scientists in 1963 is often referred to as the “detergent” of the troposphere, or the lowest part of the atmosphere, because it reacts with many pollutants and helps destroy them. It also has an important role in eliminating some greenhouse gases like methane and ozone.

Atmospheric hydroxyl radicals are so reactive that they are instantly neutralized when they make contact with any substance... This is the fact that makes hydroxyl radicals, which are in the outside air at all times during the day, one of the safest processes for deodorizing in an occupied area.

Atmospheric hydroxyl radicals should not be confused with free radicals that are produced inside living organisms. Atmospheric hydroxyl radicals are so reactive that they are instantly neutralized when they make contact with any substance and would be impossible to ingest as a complete ion. This is the fact that makes hydroxyl radicals, which are in the outside air at all times during the day, one of the safest processes for deodorizing in an occupied area.

Hydroxyls are formed in nature by the reaction of UV light from the sun disassembling water vapor (H2O) to get a hydrogen atom and oxygen (O2) which are combined together to form the hydroxyl radical (*OH).

Technology Behind Radicals

All hydroxyl generators currently used in the restoration industry incorporate some form of UV light in their process. UV light has three major spectrums: A, B and C. UVA is in the 315nm to 400nm wavelength and is what is commonly referred to as a “black light,” which makes white things glow and is considered safe for vision and skin contact. UVA lamps do not produce ozone. UVB is in the 280nm to 315nm wavelength. These are the lights in tanning salons. UVC is the 100nm to 280nm wavelength. These lamps are “germicidal” and can damage your eyes and skin. UVC lamps in the 185nm spectrum produce large amounts of ozone.

Some manufacturers use UVC lamps in the 185nm to 254nm wavelength with no catalyst whatsoever and claim to make hydroxyls. These units are nothing more that ultraviolet ozone generators and should be avoided. Other manufacturers use the same UVC 185nm to 254nm wavelength UV lamps but also incorporate reactive metals like titanium as a catalyst to create hydroxyls. These machines would probably make more hydroxyls than the first process described above but they also produce ozone and should be considered for use in unoccupied areas only.

The third technology which was developed with the National Aeronautics and Space Administration (NASA) utilizes UVC light in the 254nm wavelength to excite nano-sized particles of Titanium Dioxide to generate hydroxyl radicals. This process has been deemed safe by NASA (it has been used in the space station) and also certified by the Federal Drug Administration (FDA) as a Type 2 Medical Device that is approved for use in hospitals, including neonatal and baby wards.

The safest and most preferred technology to produce hydroxyl radicals is a version of the NASA developed process that utilizes UVA (black light) in the 365nm to 385nm wavelength to excite (irradiate) nano-sized Titanium Dioxide sol gel particles. Many scientists agree that UVA light is the best spectrum to produce the largest amount of hydroxyls possible with super reactive TiO2. The UV light used in this process is the same light that made Jimmy Hendrix posters glow in my teenage days. TiO2 is the white powder on powdered donuts or the white in your tooth paste. Both the black light and the TiO2 utilized in this technology are safe and benign.

Considerations

High volume of air movement: Since hydroxyls live less than two seconds, it is necessary and beneficial to have as much air movement as possible to move the hydroxyls out of the machine and as far away as possible in the two second time allotment. 5,000+ CFM will do a much better job than 500 to 600 CFM.

Moisture/humidity: The higher the humidity is in the treatment area the more hydroxyls will be produced and the better/quicker the hydroxyl generator will do the job. Hydroxyls are not temperature sensitive and like higher humidity which is the opposite of ozone which prefers cooler less humid conditions. 60%+ humidity is preferred for optimal hydroxyl generator performance.

Filtration: Another feature to look for in a hydroxyl generator is good filtration to help remove the oxidized particles and microbes from the air in the treatment area.

Hydroxyl Generator Purchase Considerations

Safety: Ask your hydroxyl generator manufacturer for the UV wavelength of their lamps. If they will not volunteer this information or they have lamps that are in the 185nm wavelength, consider looking elsewhere. If the hydroxyl generator you are looking at smells like ozone, it is likely making ozone. A true hydroxyl generator emits no odor at all.

Features: Get all the features you can on your hydroxyl generator. Look for the highest air volume you can get. Look for the best filtration available and look for a certified safe hydroxyl generation process that does not utilize ozone in its process. Make sure that the hydroxyl generator is sold through a network of restoration equipment retailers that can service your repair and warranty needs.

Price: Hydroxyl generator prices run the full gamut from a low of $500 to a high of $4,500. Check out the features, the hydroxyl producing process, the dealers that sell the product then make your own educated decision. Paying a lot of money does not guarantee that you will get the safest, most durable, best producing generator available. Do your due-diligence before buying.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!